by Ina Reichel

The ALS is back in user operations after a 12-week summer shutdown. Most of the shutdown work centered around ALS-U tasks, including installing a full arc sector of the accumulator ring.

Accumulator ring

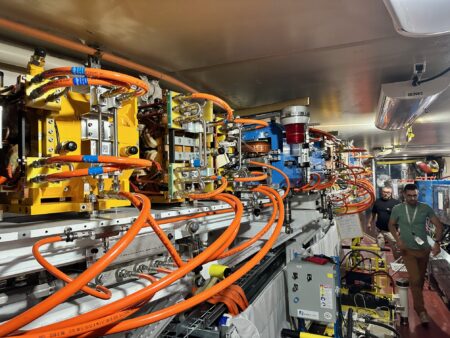

Installation of the accumulator ring (AR) and transfer line supports—key components of the upgraded ALS—continued from previous shutdowns. The first full arc sector (Sector 9) and several straight sections were installed as well as several more AR dipole magnets and magnet rafts. Each raft contains all the magnets that go in between two dipoles (or a dipole and the straight section) plus a vacuum pump. Using rafts, the team is able to preassemble the vacuum chamber and magnets instead of installing each component in the tunnel individually. The top half of the magnets needs to be removed to install the vacuum chamber, and all magnets are heavy enough that a crane needs to be involved in that work—check out the shutdown video below for a time-lapse video of a raft assembly. Most of the cable trays needed for the AR were installed as well as the supports for the AR radio frequency (rf) cavities.

For a storage ring to work, the circumference needs to be a multiple of the wavelength of the rf, so that an electron bunch on each turn “sees” the same accelerating voltage. In addition, the accelerator that feeds the storage ring usually needs to use the same rf frequency to be able to time the injected bunch properly (otherwise some rf gymnastics are required).

For the upgraded ALS, the circumference of both the AR and the main storage ring need to be multiples of the wavelength of the rf, which is about 60 cm. The chosen circumference for the AR resulted in the AR being very close to the inner shielding wall. But, the next largest circumference (60 cm more, or a radius of about 10 cm more) would have resulted in the AR taking up too much room in the walkway part of the tunnel. To allow room to install the vacuum pumps that are part of the AR, the concrete had to be shaved down by about 5 mm in four places.

Another project related to the circumference of the rings was the installation and commissioning of a new dual-frequency master oscillator. The ALS uses several rf systems (linac, booster, and storage ring). The master oscillator ensures that they are synchronized with each other so that bunches from the linac arrive in the booster at the correct phase of the rf, and again that bunches from the booster get injected into the desired bunch in the storage ring. For ALS-U, the storage ring and the AR need to operate at a slightly different rf frequency from the current system to adjust for the 30-cm-smaller circumference of the new storage ring required to avoid moving the insertion device beamlines. The linac and booster ring will keep their existing rf frequency, as the booster will not change circumference. The new system will match up phases so that any bunch of the AR can be filled from the booster despite the two rings operating at different rf frequencies.

Space planning and environment, health & safety

In the area around the transfer lines there is not enough real estate to route all cables and pipes needed for ALS-U along the wall or in existing trenches. Because it would have been impossible to cut enough additional trenches into the floor, a raised floor was installed in Sector 12, underneath which cables and pipes can be routed without creating trip hazards.

Another major project was the lighting upgrade in the storage ring tunnel. The upgraded lighting renews a system at the end of its lifetime, avoids interference with the AR, and increases the lighting brightness to comply with current fire safety rules. In the event of a power outage, instead of having a few dim emergency lights, half of the regular lights will be on at full brightness, making it a lot safer to evacuate the tunnel in case of emergency. The new system is also more energy efficient and safer to work on (low voltage LEDs instead of 277V AC fluorescent).

A new cooling system for the ALS-U electronic racks was mostly installed. They are changing from the present air-cooled system to be water cooled. A separate water circuit (process water) was required, as the water temperature for cooling the racks needs to be warmer than chilled water but colder than low-conductivity water. In addition to the new cooling loop, a third water chiller was installed, as the current system cannot handle the demands on really hot days or if one of the chillers was off.

A beam position monitor (BPM) chamber was installed and has been tested in beam operation since the shutdown. This is a prototype with several different types of BPM buttons that are planned to be used in the new main storage ring for ALS-U. In addition, the seismic retrofit work continued with the installation of more clips that will secure the accelerator tunnel walls in case of an earthquake. About 18% of the total seismic upgrade elements have been completed so far.

In addition to work inside the dome, there was also some work happening outside. The new temporary tensile structure where Building 7 was formerly located is almost finished and will be used for ALS-U staging, and work is well underway just uphill from the Guest House for the new cooling plant for Building 2.

All the work accomplished during this shutdown makes significant progress towards ALS-U. The first major segment of the AR was installed, moving far beyond the single piece of straight section vacuum chamber that was installed by the end of the previous shutdown, and a lot of logistics and other work necessary for ALS-U have been finished or progressed well.