Lubricants help keep civilization running smoothly, but is there room for improvement? Take driving a car, for example: about a third of the fuel consumed goes into overcoming friction between moving parts. The addition of tiny inorganic particles to grease-based lubricants can help reduce friction and prevent wear in mechanical systems. However, the lack of an efficient method to directly detect and monitor these microscopic particles under working conditions hinders our ability to understand their behavior and improve performance.

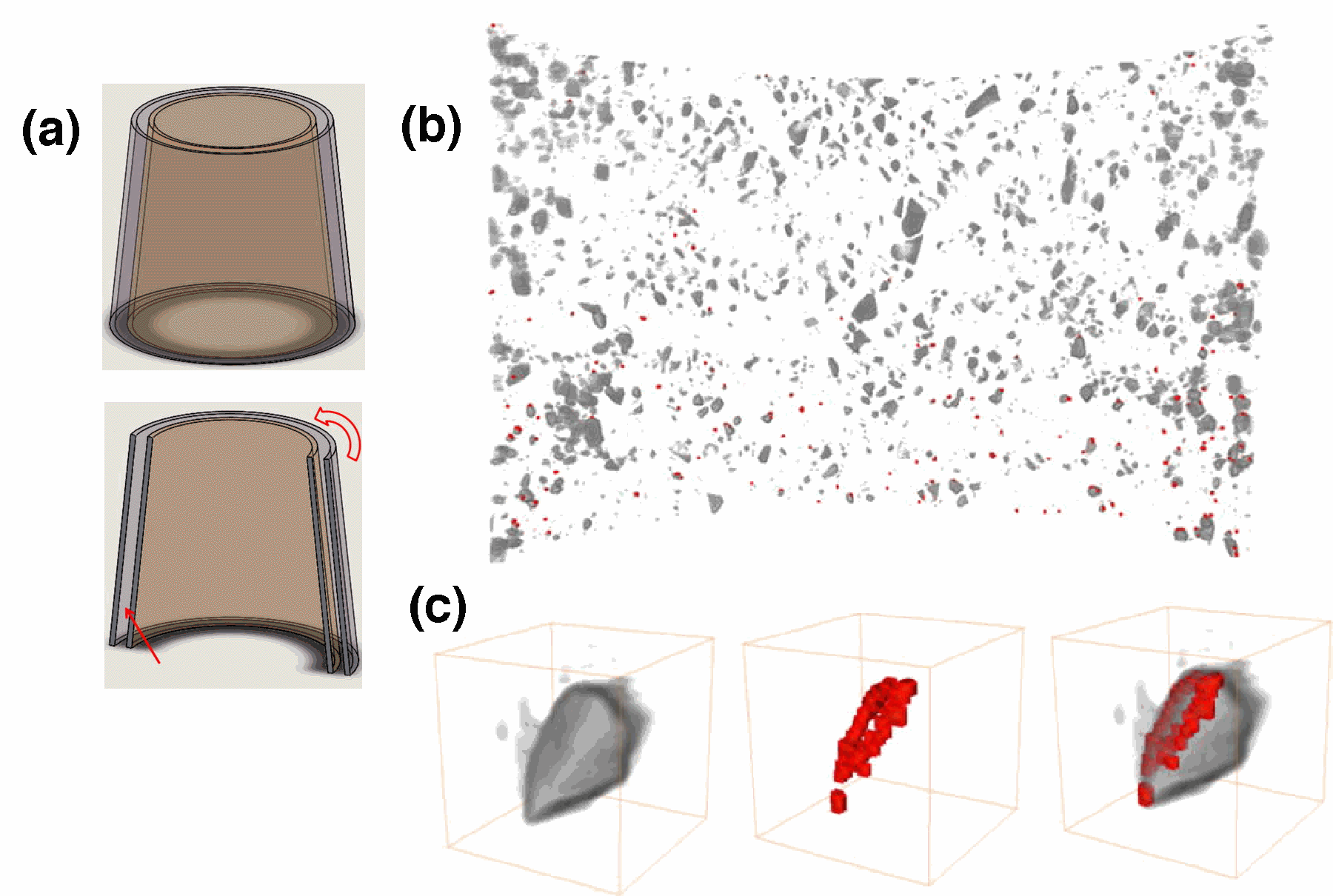

Materials scientists and mechanical engineers from Texas A&M University, including former ALS Doctoral Fellow, Yunyun Chen, have now shown that x-ray microtomography at ALS Beamline 8.3.2 can be used to visualize the distribution of iron oxide particles in a type of grease commonly used in tubing and casing connections for oil-drilling rigs. The grease samples were deposited in the gap between two concentric, conical tubes. A shear force was applied by rotating the outer tube counterclockwise at about 60 rpm.

The resulting 3D images showed that under shear stress, the iron oxide quickly adhered to specific edges of calcium-complex particles (commonly used as thickeners), possibly corresponding to the shear direction. The researchers were also able to establish a relationship between shear force and film thickness.

With this new approach, the hope is to better understand how lubricants reduce wear on moving components, increasing the life span and lowering the costs of all kinds of mechanical and biological systems, from heavy machinery to artificial joints.

Work performed at ALS Beamline 8.3.2.

Y. Chen, C. Sanchez, D.Y. Parkinson, and H. Liang, “Direct observation of lubricant additives using tomography techniques,” Appl. Phys. Lett. 109, 041603 (2016).