For the past few years, transition-metal borides have attracted a great deal of attention due to their outstanding physical properties, such as metallic electrical conductivity, high incompressibility, high shear strength, and exceptionally high hardness. These attributes are desirable in materials to be used for structural and engineering compounds and as replacements for metal carbides in next-generation cutting tools.

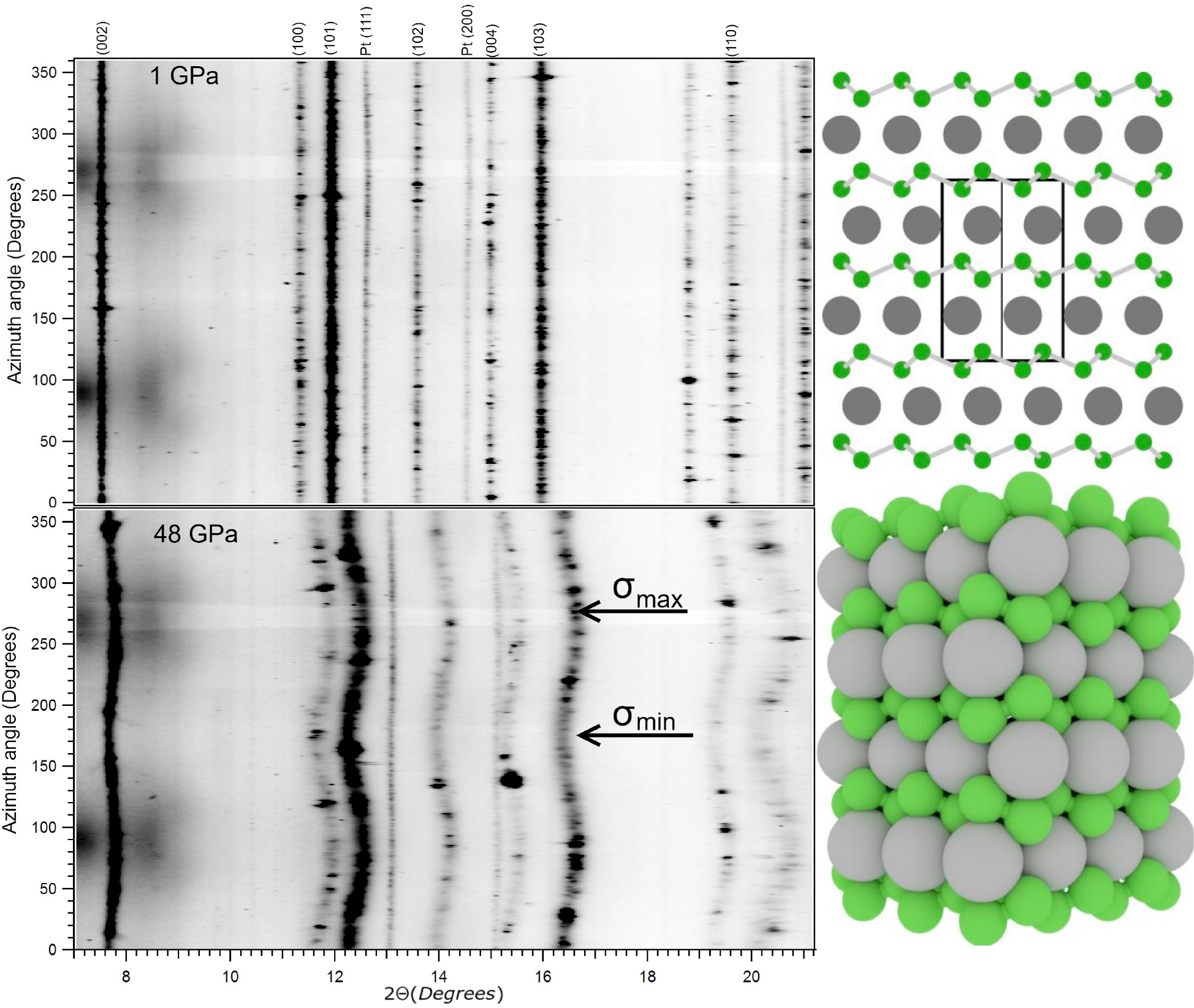

On rare occasion, mixing two materials yields better hardness characteristics than either parent material exhibits alone. To explore how to fine-tune material compositions with greater accuracy and predictability, researchers from UCLA synthesized solid “solutions” of rhenium/tungsten diboride (ReWB2), where tungsten atoms are uniformly “dissolved” into the crystal structure of rhenium diboride. They measured the material’s volume compression as a function of pressure using radial diffraction in a diamond-anvil cell at ALS Beamline 12.2.2. In this situation, diffraction signals were collected in both the high-stress (axial) and the low-stress (radial) directions.

The application of thousands of atmospheres of pressure allowed the researchers to determine the change in crystal structure at the yield point of the material. Superhard, ultra-incompressible metal borides exhibit these changes at incredible pressures, many times higher than conventional metals. The rhenium diboride solid solution maintained the rhenium diboride structure almost perfectly to the yield point.

Not only does the work represent the first experimental evidence of a solid solution of two different metal borides, it also demonstrates the accuracy of theoretical predictions about the material’s properties, opening the door to more targeted tuning of desirable characteristics by simple adjustment of chemical composition.

Work performed at ALS Beamline 12.2.2.

A.T. Lech, C.L. Turner, J. Lei, R. Mohammadi, S.H. Tolbert, and R.B. Kaner, “Superhard Rhenium/Tungsten Diboride Solid Solutions,” JACS 138, 14398 (2016).