Daniela Leitner first came to Berkeley Lab more than 20 years ago and has worked on a variety of research and operations projects in multiple divisions. Most recently, she joined the team of the ALS Upgrade project (ALS-U) as the lead for removal and installation.

Daniela Leitner first came to Berkeley Lab more than 20 years ago and has worked on a variety of research and operations projects in multiple divisions. Most recently, she joined the team of the ALS Upgrade project (ALS-U) as the lead for removal and installation.

When did you first join the Lab, and how has your career here evolved?

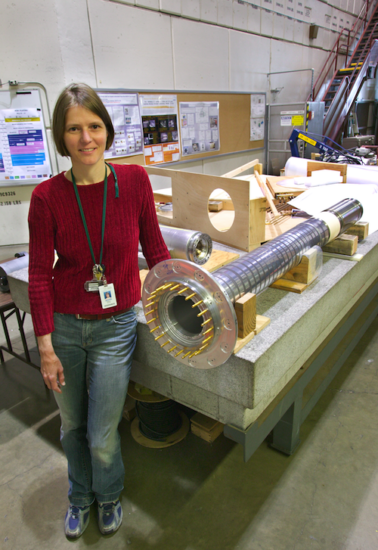

I first came to the Lab in 1996 as a postdoc. I had a fellowship from Austria to build a new ion source, and so I came to work in the Accelerator Fusion Research Division. The ion source I built with my grant turned out to be ideal for a radioactive ion beam experiment at the 88-Inch Cyclotron, so we installed it there. Following that, I moved to the Nuclear Science Division as a staff member. One of my projects was building an ion source called VENUS, which was an extremely successful electron cyclotron resonance ion source. We completed it in 2000 and it’s still the world standard that most new sources measure themselves against.

In 2010, I moved to Michigan State University for five years and worked at the Facility for Rare Isotope Beams, but then I came back to the Lab to the Engineering Division. Currently I’m the Engineering Division deputy and have my own group in Engineering focused on cross-functional support, which involves documentation and configuration, control, and CAD support for engineering, as well as quality assurance and EH&S. In February 2018 I joined the ALS-U team, and that’s now where I spend about 60% of my time.

How did you move from research to operations?

I always worked in operations to some extent by working in user facilities. In that sense, no matter where you work, it involves the same mindset that you’re here to enable science for users. Whatever research you do on your accelerator must be focused on enabling users to do better science. I find my science background helps in projects like ALS-U in that I have an easier time talking to the science groups and accelerator scientists because I have an accelerator physics background. I can relate to the science needs and can translate them into engineering requirements.

What are your primary responsibilities with the ALS-U project?

I spend most of my time preparing the plans and the design of the removal and installation, which is separate from the design of the accelerator systems themselves. My group is responsible for installing two new rings, the accumulator ring and the new storage ring, along with all the auxiliaries, and removing the old storage ring. A lot of the job is organizational interfaces, which is why an operations person is a good fit for this area. The main thing is to understand all the different pieces that need to flow into the activity.

The accumulator ring needs to be installed while the ALS is still operating, during different shutdowns. I’ve started to separate all the different activities into two- or three-day activity bins for the shorter shutdowns and six-week activities for the longer shutdowns. Even before that happens, we have preparatory work to complete on the inner wall where the accumulator ring will be installed. The storage ring will be installed during a longer “dark time” with no user operations. We’ll need to remove the old storage ring, which is 400 tons of material, and install the new storage ring. We need to arrange laydown space nearby for all the equipment awaiting installation, and we need to have a system in place to characterize all the material coming out. At the peak, 80 people will be involved in installation and removal working in crews, 16 hours a day. It’s a lot of logistics. I think 99% of my job is logistics and interfaces!

What do you like to do outside of work?

I like to go windsurfing. I also like gardening, hiking, and skiing, and I play the piano. I’ve been playing since I was eight. I don’t have much time for it between my three kids, ranging in age from 15 to 27, and my work assignments.