SCIENTIFIC ACHIEVEMENT

Using x-ray microtomography at the Advanced Light Source (ALS), researchers identified and characterized the microscale factors affecting fluid flow through shale fractures propped open with sand or ceramic spheres.

SIGNIFICANCE AND IMPACT

A better understanding of propped fractures can lead to safer and more efficient recovery of hard-to-reach oil and gas resources.

Proppants create room to flow

In shale oil and gas recovery, hydraulic fracturing (“fracking”) involves injecting pressurized fluids underground to induce fracturing of the source rock, making the extraction of otherwise inaccessible hydrocarbon resources economically viable. Eventually, the fractures close because of the weight of the ground above. To forestall this, a granular proppant material (sand, for example) is added to the fracturing fluid to act as a mechanical support, literally propping the fractures open to create room for the product to flow.

The longer the fractures remain propped, the longer a well remains usable. There are safety and sustainability benefits as well, since longer-lasting proppants reduce the need for additional re-fracturing events and require the use of less water. Although the behavior of the proppant has a direct impact on conductivity (the ease with which a fluid moves through the fractures), researchers working to optimize proppant characteristics (such as particle shape and size distribution) have lacked a quantitative understanding of proppant behavior at the microscale.

In situ x-ray microtomography

To relate macroscopic behavior to microscale processes, researchers conducted experiments using high-resolution x-ray microtomography at ALS Beamline 8.3.2, combined with detailed flow modeling. The energy and flux of Beamline 8.3.2 were crucial in enabling the collection of time-resolved, three-dimensional images of microscopic cracks in rock samples under confined uniaxial compression. Thanks to a long-term collaboration between researchers from Berkeley Lab’s Earth & Environmental Sciences Area (EESA) and the ALS, a series of groundbreaking in situ cells were developed for this beamline, including the mini high-pressure flow cell used in this work.

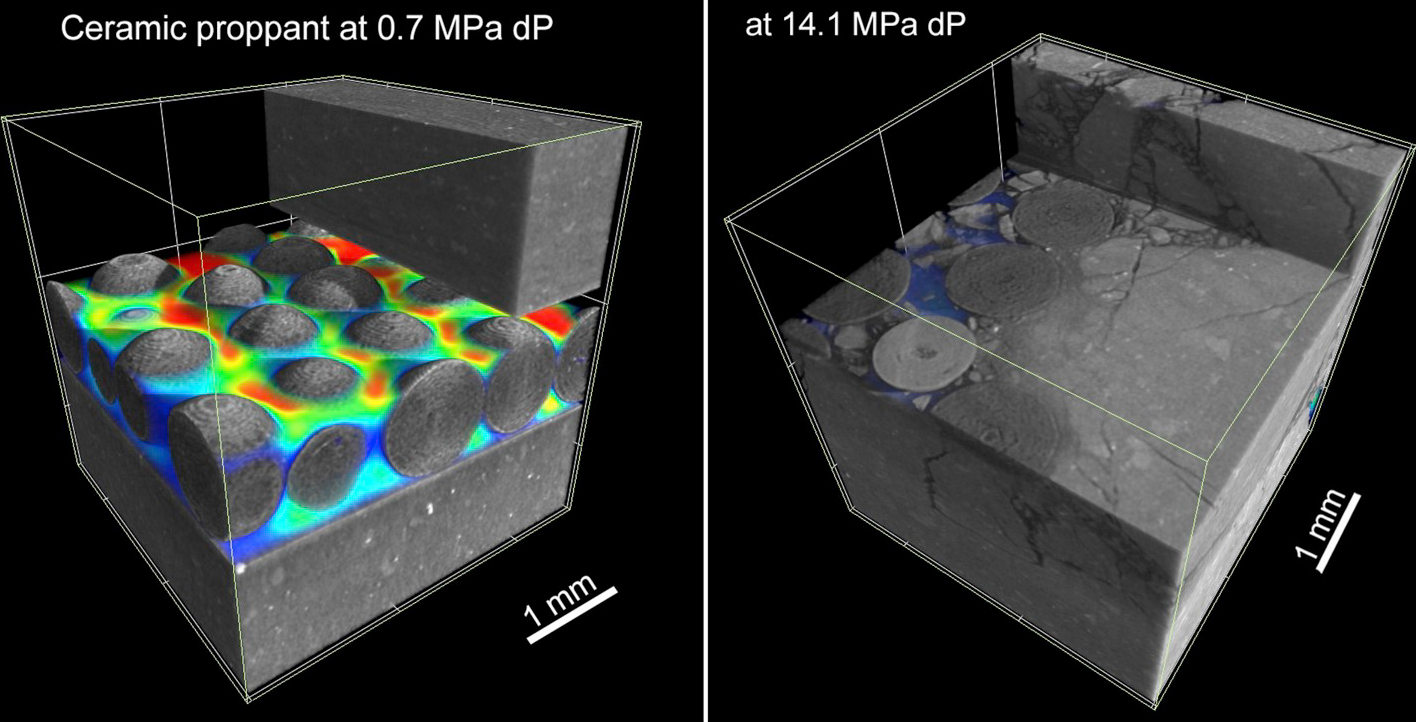

In the cell, the two most common types of proppant (quartz sand and ceramic spheres) were compressed between shale cylinders (about 4 mm high and 9 mm in diameter) in two orientations (horizontal and vertical). The shale samples came from three different deposits targeted for production in Texas (Eagle Ford), Colorado (Niobrara), and New York (Marcellus).

Insights from digital rock physics

Image-processing techniques were applied to the microtomographic data to quantify the samples’ physical characteristics, such as porosity and local thickness, as the pressure increased. Next, the researchers analyzed the data using a “digital rock physics” approach—computationally modeling key quantities such as fracture conductivity as a function of applied stress. Stokes flow simulations helped in understanding how the fluid flow changes as the fractures close.

The results showed that there are three main processes controlling the conductivity of a propped fracture: proppant rearrangement (grains rotate and translate in response to compression), proppant first breakage (largest grains begin to break down), and fracture collapse (proppant grains shatter or become embedded in the shale). One conclusion from this analysis is that, in the studied geometry, proppant rearrangement is the main process affecting conductivity. Since rearrangement is the result of irregularly shaped proppant particles, the use of uniform ceramic spheres (as opposed to quartz sand) would minimize this effect.

In general, a better understanding of micromechanical responses in rocks could lead to better oil and gas recovery procedures, as well as more effective management of problems related to induced seismicity in new and old subsurface fractures.

Contact: Marco Voltolini

Researchers: Marco Voltolini (Berkeley Lab) and Jonathan Ajo-Franklin (Rice University and Berkeley Lab).

Funding: National Energy Technology Laboratory. Operation of the ALS is supported by the U.S. Department of Energy, Office of Science, Basic Energy Sciences Program.

Publication: M. Voltolini and J. Ajo-Franklin, “Evolution of propped fractures in shales: The microscale controlling factors as revealed by in situ x-ray microtomography,” J. Pet. Sci. Eng. 188, 106861 (2020), doi:10.1016/j.petrol.2019.106861.

ALS SCIENCE HIGHLIGHT #417