Lead-free components have been increasingly used in electronics manufacturing since the European Union passed its 2003 Restriction of Hazardous Substances Directive (RoHS), which banned the use of certain hazardous materials in electrical and electronic equipment. To ensure the long-term reliability of mission-critical equipment such as networking hardware, a significant amount of research and development must be undertaken by the industry to ensure lead-free (Pb-free) metallurgies are sufficiently reliable.

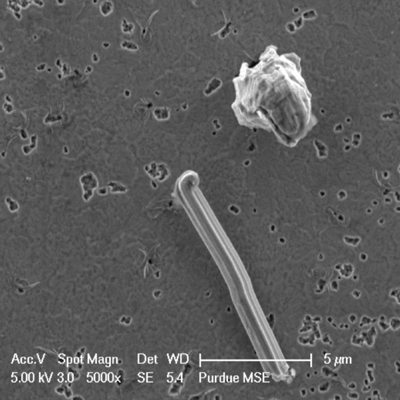

One of the unique reliability issues associated with electroplated Pb-free lead finishes [typically pure tin (Sn) or high-Sn alloys] is the growth of “whiskers,” which is the spontaneous growth of long filament-like grains on the leads, or “legs,” of electronic components. If the growth of these whiskers is not controlled, shorting between the lead can occur and thus cause system failures.

The Purdue University Materials Engineering students, led by Professor Carol Handwerker and Professor John Blendell, have been conducting whisker growth research at ALS Beamline 12.3.2 for the past three years. They use high-energy, high-resolution polychromatic x-rays to characterize the grain orientation and the strain relaxation behavior around whiskers on Pb-free electroplated Sn and SnAg3Cu0.5 (SAC305) solder films.In an effort to further understanding of whisker growth, Cisco Systems, one of the world’s largest networking equipment producers, has provided funding and technical support to a group of ALS users from Purdue University. The Purdue group is researching the fundamental growth mechanism and driving forces for whiskers, with the ultimate goal of defining effective mitigation measures.

Materials engineering PhD student and ALS user Pylin Sarobol describes the data that she and her team get at the ALS as “extremely rich” and says they value the user experience and expert advice they get from beamline scientists Martin Kunz and Nobumichi Tamura. “I’ve learned a lot by watching them operate the machine, and the software they have for extracting data is amazing,” says Sarobol.

One of the top features of the ALS that Sarobol says makes their research experience here so valuable is instant data analysis. She says the advanced data analysis capabilities save them an immense amount of time and allow them to optimize their time at the ALS since they are able to immediately discern whether their scans are giving them the results they need.

“When we first started in 2009 we had to take our data back and spend six months analyzing it,” says Sarobol. “Now the ALS offers us instant data analysis, which means we can make sure that what we think will work is working; it really speeds up our research process.”

Their scans have shown lower grain orientation spread, orientation changes, and lower dislocation density in the whisker grains compared to the parent grains, suggesting recrystallization as the nucleation mechanism of the whisker grains. While the theory of recrystallization as the nucleation mechanisms for whiskers has been around since 1958, the data that this group collected at the ALS provided the first experimental results that truly confirmed the theory.

“We were able to see that the atomic arrangement in the whisker grain is very different from the others,” says Sarobol. “This was the first direct experimental evidence of whisker formation by recrystallization, which was really exciting for us. We have also successfully identified the differences in crystallographic texture between whisker-prone regions and whisker-free regions in the finish, which will offer important clues for developing plating chemistry and processes.”

“We hope to gain further in-depth knowledge of whisker growth mechanisms and the approaches to mitigate risk, both at the component level and at the system level.” says Dr. Peng Su, project lead at Cisco Systems, “It will help us and the industry to outline more effective approaches to ensure long-term reliability.”