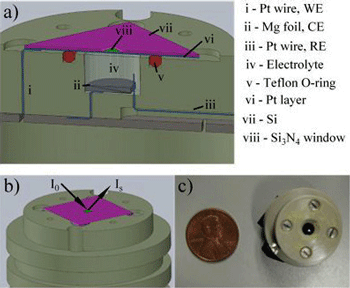

Toyota is investing heavily in magnesium battery research, with $100K of their annual research budget going to the ALS. Beamline 6.3.1 scientists are studying magnesium battery performance and degradation with a unique new endstation that offers in situ electrochemical soft x-ray capabilities. High-vacuum conditions typically preclude the synchrotron analysis of liquid Mg electrolytes.Alternatives to the current lithium-ion-based car batteries are at the forefront of the automotive industry’s research agenda—manufacturers want to build cars with longer battery life, and to do that they’re going to have to find new solutions. One promising battery material is magnesium (Mg)—it is more dense than lithium, it is safer, and the magnesium ion carries a two-electron charge, giving it potential as a more efficient energy source. Magnesium has a high volumetric capacity, which could mean more battery power in a smaller space. However, to bring Mg batteries to the commercial market, researchers must create new electrolytes with improved properties. The x-ray absorption spectroscopy (XAS) facilities at the ALS are vital to understanding the interfaces and active species in Mg batteries.

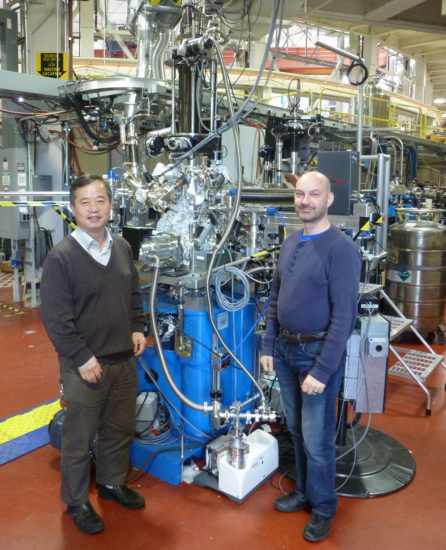

ALS staff scientists Jinghua Guo and Per-Anders Glans-Suzuki and Toyota Scientist Timothy Arthur have developed a specialized in situ chamber to study the complex electrochemical Mg reduction process at Beamline 6.3.1. Through in situ electrochemical XAS techniques, Arthur, Glans-Suzuki and Guo are able to study all phases of battery life, including transient states. The data they’re collecting is giving them valuable insight into the development of next-generation Mg electrolytes. The endstation they developed is a challenging and unique configuration that’s not currently available anywhere else in the world.

Though intellectual property limitations were challenging when Toyota and the ALS began negotiating how they could work together, the partnership worked out smoothly because the research is currently at such a fundamental level, says Guo.

“Through in situ electrochemical XAS techniques, we have gained valuable insights toward the development of next generation Mg electrolytes,” says Arthur.

Read more about this research at ScienceDirect.