SCIENTIFIC ACHIEVEMENT

TE Connectivity used ALS microtomography capabilities to optimize the material and manufacturing parameters of their conductive plastics to impart good electrical conductivity.

SIGNIFICANCE AND IMPACT

Conductive plastics with good electrical properties offer processing and cost benefits over metal alternatives, with applications ranging from automotive to data communications.

The benefits of conductive plastics

Conductive plastics combine the benefits of plastics, such as mechanical flexibility, good manufacturability, and chemical resistance, with desirable electrical conductivity (imparted by metal particle fillers). Compared to traditional metal alternatives, they are cheaper and easier to process. Conductive plastics have a wide range of applications, including electrical connections, electrodes, sensors, antistatic devices, and electromagnetic interference shielding. TE Connectivity, a $13 billion global technology and manufacturing company, uses conductive polymers in a wide variety of industries, from automotive to data communications.

“There are a lot of benefits to using conductive plastics as opposed to metal—you can mold them using techniques that you use to mold traditional plastics, using affordable high-volume manufacturing techniques, or you can 3D print,” says Megan Beers, a staff scientist in TE Connectivity’s materials and integrated electronics technology center. “Conductive plastics really provide design freedom to our product engineers.”

Fine-tuning the material and manufacturing parameters

The processing parameters of conductive plastics are key to their conductive properties—more or less of a certain material or an adjustment to heat levels during manufacturing can produce vastly different results. In an effort to understand more about how to fine-tune their conductive plastic materials and the manufacturing process, TE Connectivity began using the microtomography capabilities at ALS Beamline 8.3.2 in 2014.

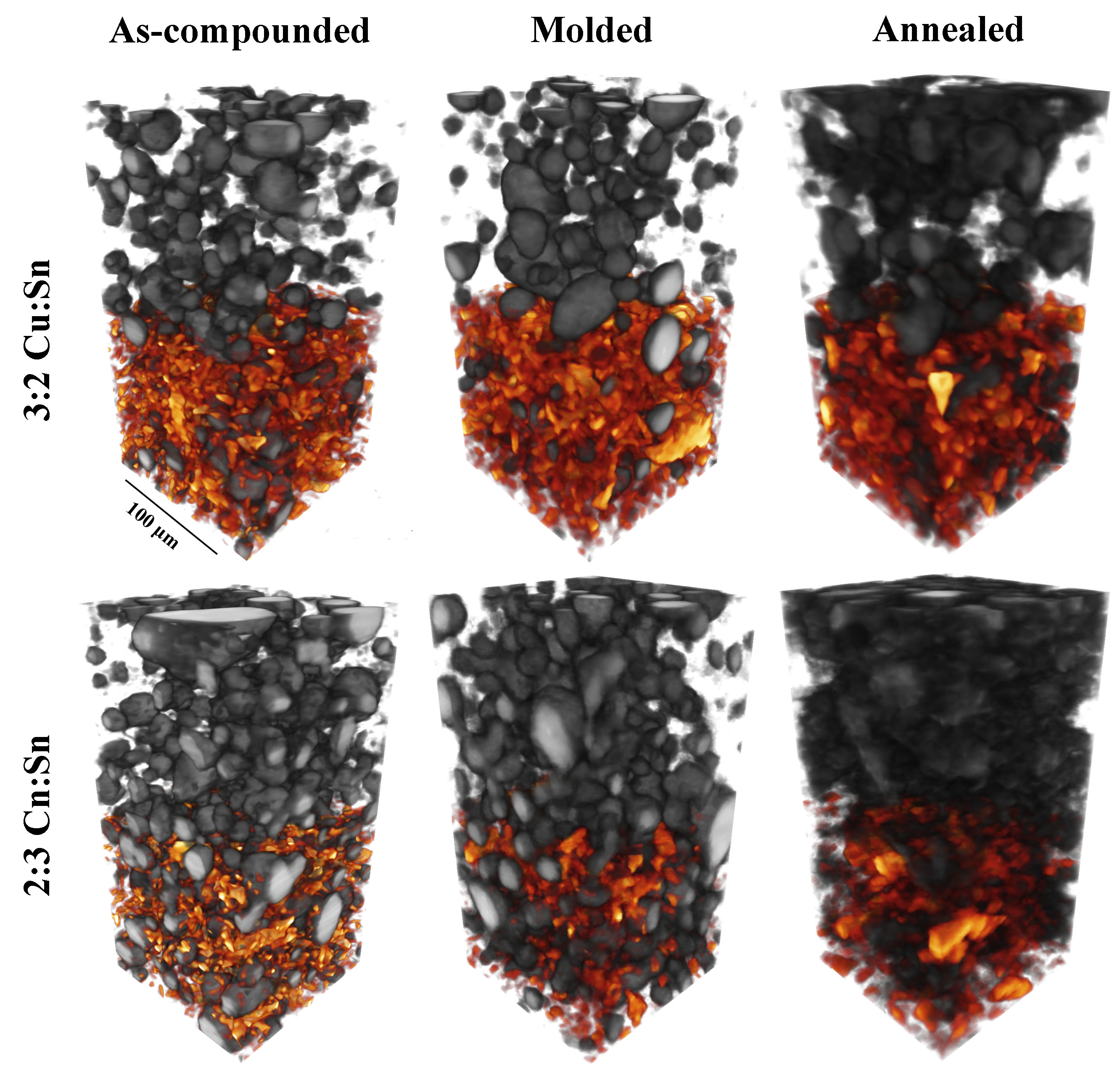

TE and ALS scientists built a special heating stage at the beamline so they could image their conductive plastic samples in 3D at the micrometer scale at various temperatures. They had observed that a sample containing electrically conductive copper and tin particles had poor conductivity after the initial injection molding process. However, once they annealed the sample at high temperature, the ALS results demonstrated that the particles redistributed within the material to impart very good electrical conductivity.

“Looking at the beamline images of these samples before and after annealing, you could clearly see how the tin material had completely redistributed around the copper particles to give the composite a really nice conductive network,” says Beers.

In situ measurements provide further insight

The thermal stage that TE built at the beamline also allowed them to perform in situ measurements on their conductive plastic materials. “While thermally annealing, we were able to watch as electrical conductivity improved and at the same time particles redistributed over time,” says Beers. “We could coordinate the redistribution of particles with changes in electrical properties, which helped us understand more precisely how annealing improved conductivity.”

“During these experiments at the ALS we saw that not only were the particles rearranging, but we saw new metal intermetallic structures that were forming,” says Beers. “The high power of the x-rays and ability to use different energies of the x-rays gave us a lot of really detailed information about the distribution of metals in our samples.”

The mutual benefits of collaboration

During this project, TE forged a close partnership with ALS Beamline Scientist Dula Parkinson and funded a postdoc to run its research at the ALS for two years. “Dula [Parkinson] has been a huge help to us in getting the most out of our beamline research,” says Beers. “When we have questions he’s always willing to sit down with us and figure out options, and when we’re not getting the results we need he can always solve it for us; sometimes he comes up with a whole new analysis technique.”

“Working with TE was a really positive thing for us as well,” says Parkinson. “We had a postdoc funded, we built a heating stage that we’re still using, and we made progress on analysis methods that have since been applied to other projects as well.”

Researchers: Q. Yang, M.H. Beers, V. Mehta, M. Zheng, T. Gao, R. Lloyd, T. Gao (TE Connectivity); D. Parkinson (ALS).

Funding: TE Connectivity. Operation of the ALS is supported by the U.S. Department of Energy, Office of Science, Basic Energy Sciences Program (DOE BES).

Publications: Q. Yang, M.H. Beers, M. Zheng, R. Lloyd, T. Gao, D. Parkinson, “In situ electrical resistance and X-ray tomography study of copper–tin polymer composites during thermal annealing,” J. Appl. Polym. Sci. 134, 43 (2017), doi:10.1002/app.45399; Q. Yang, M.H. Beers, V. Mehta, T. Gao, and D. Parkinson, “Effect of thermal annealing on the electrical conductivity of copper–tin polymer composites,” ACS Appl. Mater. Interfaces 9, 1 (2017), doi:10.1021/acsami.6b13956.