Chemistry at the Advanced Light Source (ALS) is everywhere—not just inside the materials being studied, but also within teams of researchers collaborating on their science. The facility boasts some of the world’s brightest x-rays, infrared, and extreme ultraviolet light and serves as a rare resource that advances the research of thousands of visiting users each year. But what attracts many researchers, including companies with tight deadlines and development milestones to meet, are the highly specialized equipment and access to experts who can accelerate their work.

Access to both equipment and expertise appealed to Tim Arthur, principal scientist at Toyota Research Institute. Although Toyota has a dedicated beamline at the SPring-8 synchrotron in Japan, Arthur opted to bring his project on magnesium-ion batteries to the ALS. “It’s the best place in the world for soft x-rays,” he said.

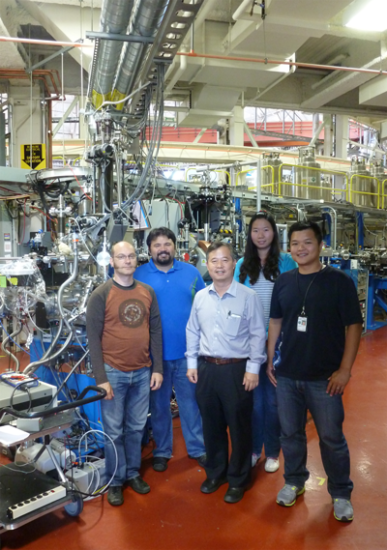

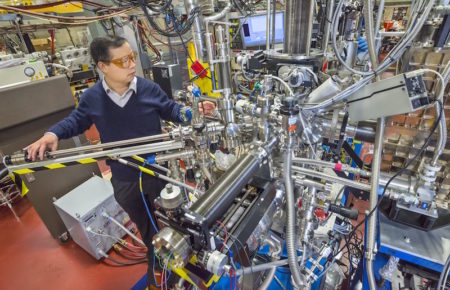

While some researchers send their students or postdocs to run the experiments, or even mail in their samples, Arthur was motivated by the Toyota way of genchi genbutsu, or “go see for yourself.” During the five-year collaboration with ALS scientists Jinghua Guo and Per-Anders Glans-Suzuki, he traveled to the ALS about 20 times. Before each trip, Guo’s team would apprise him of technology updates that would improve their planned experiments, and Arthur would arrive before the assigned beam time to share ideas.

That same collaborative spirit brought James Fraser as a UC Berkeley student to the ALS to work with Beamline Scientist James Holton. Now an associate professor at UCSF, Fraser and Holton’s decade-long partnership has yielded an experimental set-up that benefits pharmaceutical companies like Relay Therapeutics.

Relay Therapeutics’ approach to drug discovery depends on collecting protein motion data over a range of temperatures, which offers substantially more insight than the more widely available technique of measuring frozen, stationary proteins. The company’s close collaboration with Holton and Fraser provided the expertise and flexibility needed for their work.

“Most beamlines available to industry in the world are not set up to do the kind of exploratory work we need to push the boundaries of structural biology and drug discovery,” said Relay scientist Pascal Fortin. “The ALS was the only place where we could do our research.”

Some industry users depend on facilities like the ALS to advance research they prefer to keep proprietary, or trade secret. In return for access, they pay a cost recovery fee. Others, however, opt for free, non-proprietary beam time in exchange for publishing their results openly and contributing to scientific knowledge.

“It’s so much better to be open,” Arthur said, “That’s Toyota’s stance on early stage research.”

Guo further explained that the “best” battery by experimental standards—the information that a publication focuses on—may differ from what a company considers a good product that is safe and convenient for consumers. Thus, developing a competitive product is not necessarily at odds with publishing experimental results.

Connector and sensor company TE Connectivity also took advantage of non-proprietary beam time at the ALS and published the results of their 3D imaging of conductive composites.

“What we wanted to find out about the materials was very general and fundamental,” said Megan Beers, staff scientist at TE Connectivity. “It was our intention from the beginning to share our results.”

The company went one step further by hiring a postdoc, Qing Yang, to work with ALS Beamline Scientist Dula Parkinson. Yang worked closely with the Center for Advanced Mathematics for Energy Research Applications (CAMERA) on software improvements necessary to keep up with ever-increasing amounts of data. Their collaboration not only improved TE Connectivity’s understanding of their materials, but subsequent users have benefited from both the software and the in situ heating stage that Yang developed as well.

“It’s easy to apply algorithms on test data, but problems come up when you apply them to the real world,” Parkinson said. “It was really useful to have a postdoc dedicated to the conductive composites project, because that gave a use case to advance the algorithms.”

The fundamental research industry conducts at the ALS might lead to products that will make our daily routines more convenient or even save our lives. More importantly, their team chemistry has wider-reaching impacts, enabling possibilities, benefits, and applications that are yet to be conceived.