Upon deformation, some metal alloys can “remember” their original form and return to it repeatedly when heated. Called “shape memory alloys,” these materials have emerging applications in medical devices (stents, artery guide wires, and heart valves) and microelectromechanical actuators and sensors. Usually, within a few cycles, the reversibility of the transformation is lost and the functionality of the material degrades.

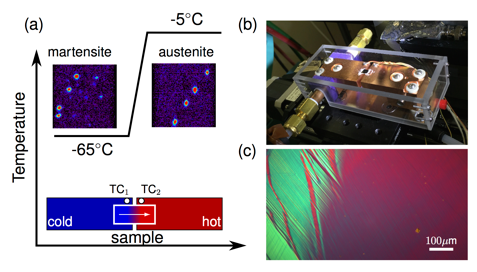

Recently, researchers synthesized an alloy of copper, gold, and zinc (Cu25Au30Zn45) that exhibits a highly reversible shape transformation, capable of sustaining tens of thousands of temperature cycles without failure. Its formula was chosen by systematically tuning the composition so that the crystal lattice parameters of the high- and low-temperature phases (“austenite” and “martensite,” respectively) satisfied certain conditions for compatibility. Upon cycling, optical micrographs of the phase boundary showed unusual, curvy microstructures, in sharp contrast to traditional shape memory alloys.

To gain structural insight, the researchers performed x-ray Laue microdiffraction at ALS Beamline 12.3.2, using a custom-made temperature-gradient stage. The orientations and structural parameters of the phases near the martensite/austenite interface, together with theoretical calculations, verified that the alloy’s high reversibility and the formation of fluid-like microstructures were closely related to a high degree of lattice compatibility between the two phases. The advanced structural characterization methods used here demonstrate and verify that mathematics can guide the discovery of new materials with exceptional properties, opening the possibility of creating functional materials with high mechanical reliability on demand.

X. Chen, N. Tamura, A. MacDowell, and R.D. James, “In-situ characterization of highly reversible phase transformation by synchrotron X-ray Laue microdiffraction,” Appl. Phys. Lett. 108, 211902 (2016).