It was 10 years ago that ALS Senior Staff Scientist Eli Rotenberg devised the name Microscopic and Electronic STRucture Observatory, or MAESTRO, for his long-envisioned beamline dedicated to the determination of the electronic structure of materials at the mesoscopic length scale. This September, the beamline, 7.0.2, will accept general user proposals for the first time, offering researchers unparalleled opportunities for studying the correlation between structure and electronic properties.

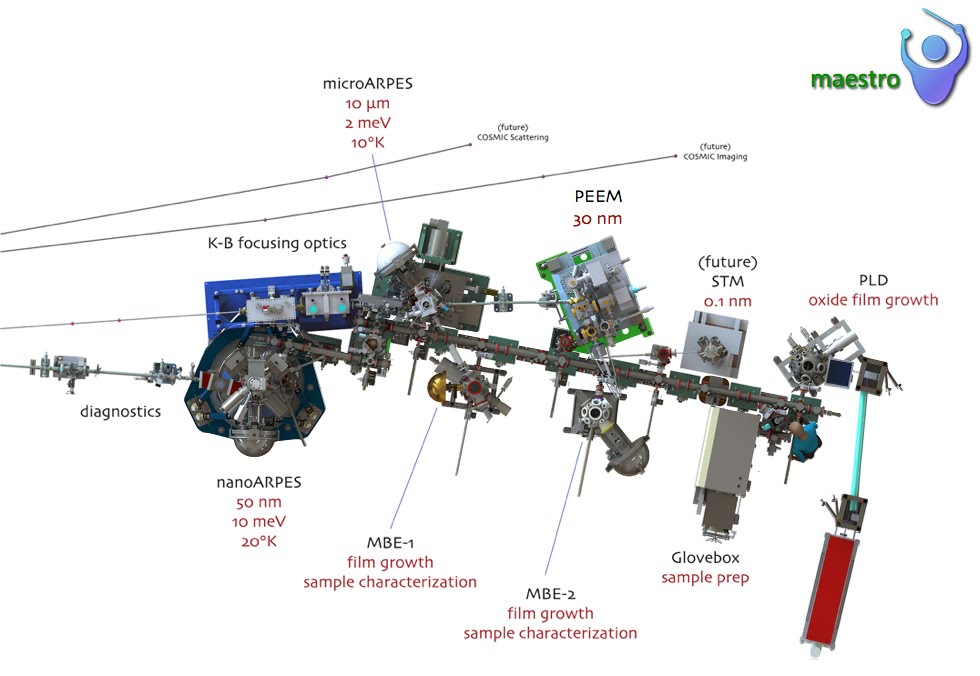

MAESTRO’s unique attributes combine strong sample preparation capabilities with cutting-edge spectromicroscopy tools. Sample preparation is done at the beamline itself in one of three sample preparation chambers. The first is molecular beam epitaxy (MBE), with capabilities that rival those of dedicated laboratories not connected to a synchrotron. The second is pulsed laser deposition (PLD), typically used for oxides like high-Tc superconductors. The third sample preparation area is simple, but essential—an atmosphere-controlled glovebox. All of the chambers offer the critical ability to prepare clean, highly crystalline samples in a non-reactive environment, then move them into a beamline endstation for analysis without them ever leaving the beamline enclosure.

The beamline provides three ARPES (angle-resolved photoemission spectroscopy) endstations, each with different strengths. MicroARPES allows the best energy resolution and lowest sample temperatures (down to 12 K) among them, but at the expense of spatial resolution, which is limited to ~10 μm. The second endstation offers photoemission electron microscopy, or PEEM, which illuminates a large region of the sample to perform full-field electron microscopy on it. Although PEEM is relatively easy and quick and offers a spatial resolution of 30 nm, a sample grain has to be at least 3 μm to perform a spatially selected ARPES measurement.

The third endstation, featuring nanoARPES, is still undergoing testing but will eventually offer the best spatial resolution of the endstations at 50 nm. In the future, Rotenberg says the resolution may get better, particularly if the proposed ALS upgrade (ALS-U) comes to fruition. “With ALS-U we could probably get to 25 nm easily, and with other tricks we could eventually get down to 5 nm.” The drawbacks of nanoARPES are a low count rate (at least 100 times worse than with microARPES) and the potential for sample damage from high energy densities.

The endstation complex, designed by Geoff Gaines, Aaron Bostwick, Chris Jozwiak, and Rotenberg, is linked by an elaborate, automated sample transfer highway called MART—MAESTRO Area Rapid Transit. MART is a sample “railway” with custom robotics for automated transfer of samples in an ultra-high vacuum (UHV) environment. Like commuter train systems, traffic congestion is reduced by providing dual tracks and plenty of in-vacuum storage slots—nearly 300 samples can be stored in UHV and directed to where they are needed. The commissioning of MART and the endstations began last fall and has been carried out with visiting postdoctoral fellows Daniel Schwartz, Soren Ulstrum, Roland Koch, Hyang Keun Yoo, Luca Moreschini, and Simon Moser.

The unique capability of automated transfer among multiple sample preparation chambers and multiple synchrotron endstations opens up a wide range of possible experiments. “We’ll have the ability to prepare a surface that’s atomically precise in the MBE chamber, then you could bring that sample to the glovebox and exfoliate a sensitive material onto it. You could even imagine depositing atoms on top of that and coming back to the glovebox to lay something else down on it,” described Rotenberg. “There are bits and pieces [of the beamline] that have similar qualities to other instruments around the world, but there’s no other beamline that has everything in one place,” said Rotenberg. “It allows us to tackle harder problems.” Among those could be synthesizing and measuring sandwiches and heterostructures with high atomic precision or exotic materials like high-Tc cuprates made of a single superconducting layer.

In terms of user access, there are opportunities and challenges to the beamline’s many offerings. On one hand, there are multiple chambers for sample growth, all of which could be occupied by different groups at once. Preparing a sample in the MBE chamber might take a group two weeks, but with PLD, more than one sample could be grown in a day. The glovebox offers even more flexibility. With so many variables in play, it can be difficult to determine well in advance when a sample might be ready for beam time. That’s a primary advantage of the sample storage system—the samples can staged for analysis without ever exposing them to the atmosphere.

Although the beamline will accept proposals from general users beginning with the upcoming September 7 deadline, a significant fraction of beam time will be reserved for rapid access (RAPIDD) proposals and continued beamline optimization. General user applicants for beam time and those interested in using the sample preparation chambers should contact Rotenberg before submitting a proposal.