SCIENTIFIC ACHIEVEMENT

Using microtomography at the Advanced Light Source (ALS) and other techniques, researchers identified the exoskeletal toughening mechanisms that explain the crush resistance of the aptly named diabolical ironclad beetle.

SIGNIFICANCE AND IMPACT

The observations could be applied in developing tough, impact- and crush-resistant materials for joining dissimilar materials.

Diabolically tough construction

Stepped on by a hiking boot? Not a problem. Run over by a car? Good to go. The appropriately named diabolical ironclad beetle can take a shelling thanks to the incredibly crush-resistant architecture of its exoskeleton, which could serve as the blueprints for designing tougher materials and stronger connections between different material types.

Joining dissimilar materials such as plastics and metals in engineered structures has always been a challenge. Mechanical fastening, welding, and adhesive bonding are currently used methods, but each presents its own set of problems, such as the formation of stress concentrators or degradation under environmental exposure.

Ironclad lessons from nature

For millions of years, environmental pressures and predator–prey relationships have driven arthropods (including insects, spiders, and crustaceans) to develop structures that are both mechanically robust and multifunctional. With over 350,000 species of flying, terrestrial, and aquatic variants, efficient strategies have evolved to synthesize, construct, and integrate composites that have exceptional mechanical properties.

In particular, the Zopherinae (“ironclad”) family of insects are known for their compression resistance. Evolved from flying ancestors, these terrestrial beetles have forewings (elytra) that are fused into an armor-like exoskeleton. The diabolical ironclad beetles studied in this work are primarily found on the western coast of North America, under the bark of hardwood and coniferous trees, playing dead and superficially resembling a small rock.

Microscopic architecture in 3D

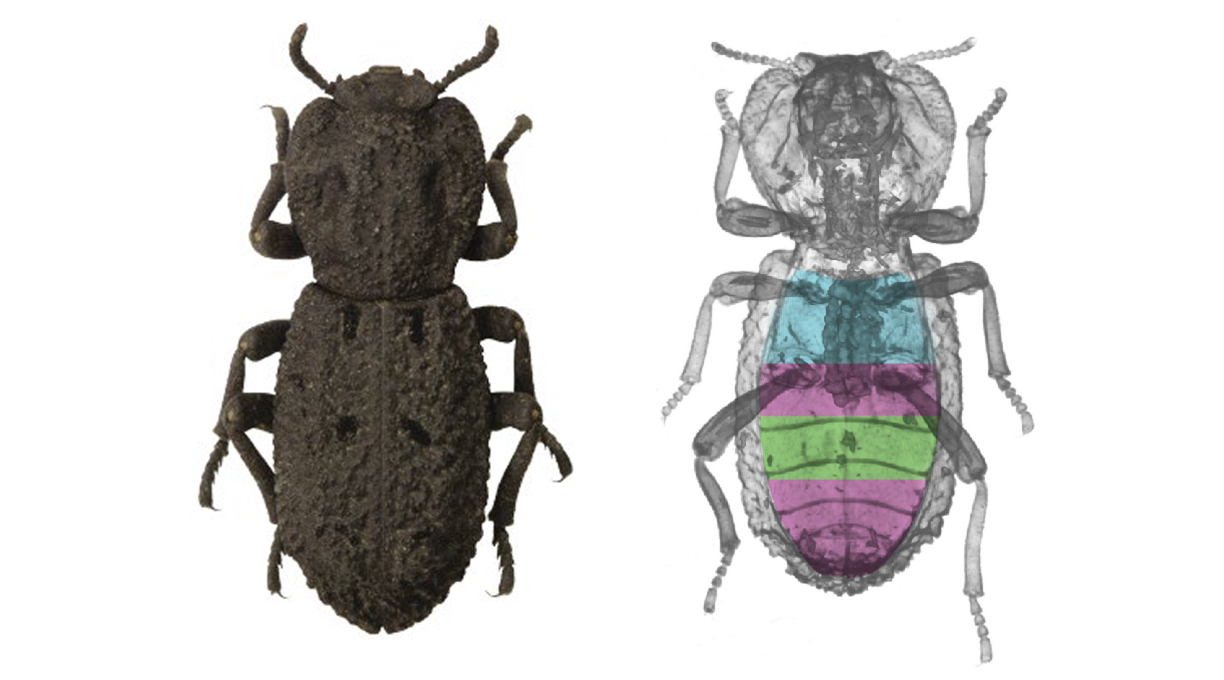

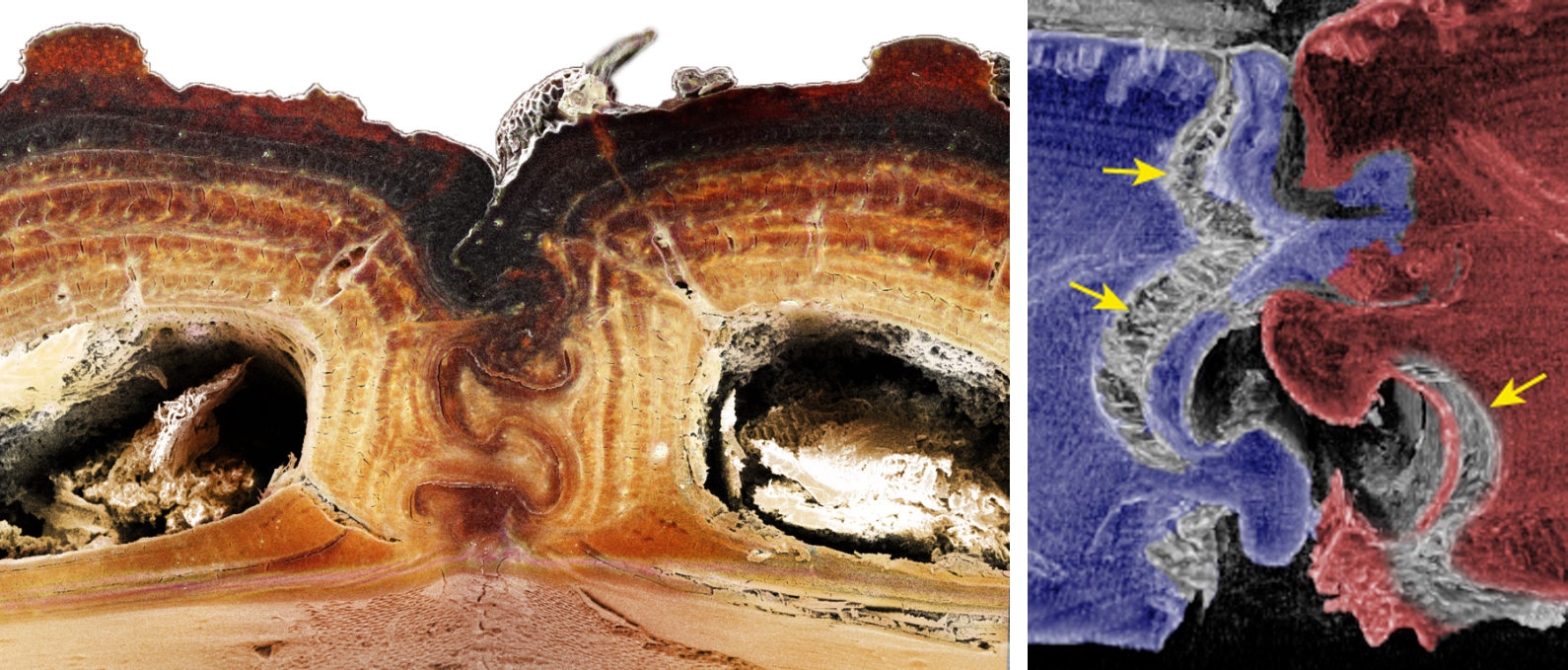

To see what makes this beetle so tough, researchers used scanning electron microscopy and x-ray computed tomography at ALS Beamline 8.3.2 to visualize its elytra, abdomen, and other parts. The x-rays’ ability to penetrate the exoskeleton enabled high-resolution 3D imaging that was critical to understanding the characteristics of the beetle’s microscopic interlocking seams.

In addition to the structural characterizations, the researchers also performed compositional analyses, compression tests, and computer simulations of the material’s responses to mechanical stress. Finally, they fabricated composite junctions modeled after those found in the beetle and compared their performance to mechanical fastenings found in turbine engines and aerospace structures.

Three interfacial joint motifs

The study revealed three distinct joint motifs at the interface between the beetle’s elytra and its bottom shell (the ventral cuticle). Together, these variations (interdigitated, latching, and free-standing) provide maximum stiffness where needed to protect vital organs as well as the flexibility to absorb energy and distribute load uniformly. The top seam where the elytra are fused (the medial suture) was secured by interlocking “blades” that resemble jigsaw puzzle pieces. The blades’ elliptical geometry confers greater strength compared to the hemispherical and triangular analogues found in other species. Failure of the elliptical blades was found to occur by layer separation (delamination), which helps avoid catastrophic failure at the blade neck.

The design strategies revealed by this study can be used to improve joinings between dissimilar materials such as plastics and metals: fabricated blades incorporating these ideas proved to be slightly stronger than current engineering fasteners and substantially better at energy dissipation. By tuning material parameters, the researchers hope to further improve these interdigitated interfaces for tougher, more impact- and crush-resistant structures.

Contact: David Kisailus

Researchers: J. Rivera and D. Vasile (Univ. of California, Riverside), M.S. Hosseini and P. Zavattieri (Purdue Univ.), D. Restrepo (Purdue Univ. and Univ. of Texas at San Antonio), S. Murata and A. Arakaki (Tokyo Univ. of Agriculture and Technology), D.Y. Parkinson and H.S. Barnard (ALS), and D. Kisailus (Univ. of California, Riverside, and Univ. of California, Irvine).

Funding: Air Force Office of Scientific Research, Army Research Office, and Institute of Global Innovation Research at Tokyo University of Agriculture and Technology. Operation of the ALS is supported by the U.S. Department of Energy, Office of Science, Basic Energy Sciences program.

Publication: J. Rivera, M.S. Hosseini, D. Restrepo, S. Murata, D. Vasile, D.Y. Parkinson, H.S. Barnard, A. Arakaki, P. Zavattieri, and D. Kisailus, “Toughening Mechanisms of the Elytra of the Diabolical Ironclad Beetle,” Nature 586, 543 (2020), doi: 10.1038/s41586-020-2813-8.

Adapted from the Berkeley Lab news release, “X-Rays Reveal Architectural Clues to the Crush-Resistance of Diabolical Ironclad Beetles.”

ALS SCIENCE HIGHLIGHT #433