The Environmental Protection Agency (EPA) has been investigating biofuels for several years now as part of its mission of moving the nation toward a cleaner energy future. Recently, EPA scientists have refocused their research on a promising biofuel byproduct—biochar, which is the solid material that’s left behind after biomass goes through thermochemical decomposition at elevated temperatures in the absence of oxygen (pyrolysis). Since ancient times, people have been using biochar as an amendment to enrich soil, but recent research has shown biochar to also be extremely effective carbon-neutral soil amendment for environmental remediation. Using ALS Beamlines 10.3.2 and 8.3.2, the EPA is currently investigating how biochar sorbs environmental toxins and which kinds of biochar are the most effective. The possibilities for widespread use have already launched entrepreneurial commercial ventures.

Biochar can be produced using many different raw materials, from agricultural waste to timber scraps. Throughout the U.S., there’s an abundance of raw material being produced or sitting in waste sites ready to be converted to biochar—the Northwest has the timber industry, for example, while the Midwest produces a huge amount of agricultural waste such as wheat straw and corn stover from small grain production. The biochar that’s produced from each of these materials has different properties and patterns of sorption, and understanding this will be key to determining what types of biochar will most effectively remediate various environmental contaminants.

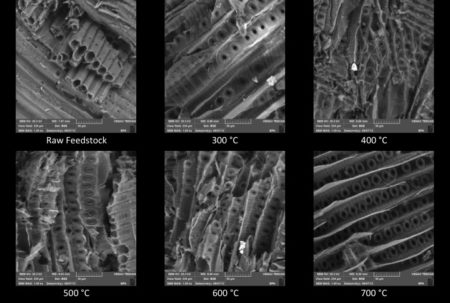

Given that the physical and chemical characteristics of biochar change under different pyrolysis production conditions, the mechanisms of metal sorption are also likely to change, thus affecting its efficacy for use in environmental remediation. The EPA is using the ALS to further understand the relationships among biochar feedstock, pyrolysis procedure, and metal/chemical sorption potential, and the nature and mechanisms of metal/chemical sorption on biochars.

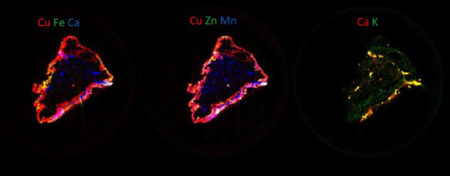

Using ALS tomography capabilities, the EPA is gaining key data about biochar sorption patterns. Mark Johnson, a research soil scientist at the EPA, says that at ALS Beamline 10.3.2, his team was able to literally map metal absorption on the external and internal surfaces of biochar materials and characterize the electronic structure of their bonding environment. They then used Beamline 8.3.2 to further understand how the subtle changes in the density and structure of biochar affects the patterns of metal sorption.

“We were literally able to ‘take a ride’ through the structure of these particles, seeing where density changed and where absorption was the greatest,” says Johnson. “It’s only been with the tools at the ALS that we’re able to figure this out.”

The top industrial application for biochar would be environmental remediation – biochars have proven effective at absorbing herbicides, pesticides, and chemicals as well as metals, such as those found at mining sites. However, not all biochar feedstocks and charring procedures (e.g., heating profiles, maximum pyrolysis temperature, activation) produce the same quality of biochar, nor do they have the same remediation potential. Determining which biochars work best on which contaminants will be key to effective use and production, says Johnson.

Johnson recently tested a mine spoil laden soil collected from a superfund mining site in Colorado at the ALS and found certain biochars particularly effective at absorbing various metals. Biochar derived from Douglas-fir wood chips was very effective at removing copper and lead, but had little effect on cadmium and zinc. The metal sorbing capabilities of biochars go beyond superfund sites – one example Johnson cites is that of salmon spawning season in the Pacific Northwest. Salmon eggs are deposited in the fall, which is also when road runoff from the first rains of the season contains a lot of metal, in particular copper off roadways from brake linings. Copper affects the fear factor of young fish – even with a small amount present in the water, young fish are dangerously unaware of their predators. “If we could use biochar filters to remove copper before runoff enters the streams and rivers, we could capture the copper before it gets to the salmon eggs,” says Johnson. Likewise, in agricultural sites, a biochar-based filter strip could prevent chemicals and pesticides runoff from entering streams or rivers, says Johnson.

Entrepreneurs are catching on to the widespread potential for biochars. Johnson cites a company that’s unearthing landfill sawmill wastes to produce biochar. There’s huge opportunity for new business growth, with an ample supply of raw material. In 5 to 10 years biochar research and development should be at the point where the material is in widespread use, says Johnson. And at that point, the demand will be high – one mine site could easily need tons of biochar for remediation, he says.

“As we figure out the mechanisms for sorption, the ALS is a really important arrow to have in our quiver,” says Johnson. He and his research colleagues, EPA Post Doc Jonathan Maynard and ALS Staff Scientist Peter Nico, appreciate all the assistance that the ALS beamline scientists Matthew Markus, Sirine Fakra, Dula Parkinson, and Josep Roque-Rosell have provided to help their research succeed.