As crystalline materials experience stress, their grains—and the boundaries between them—slide, rotate, diffuse, and dislocate. This process of “plastic deformation” is critical to determining a material’s strength. Although plastic deformation is well understood at the micrometer scale, the mechanisms controlling nanometer-scale deformation are much more difficult to probe, although grain rotation has been suspected to be the dominant factor.

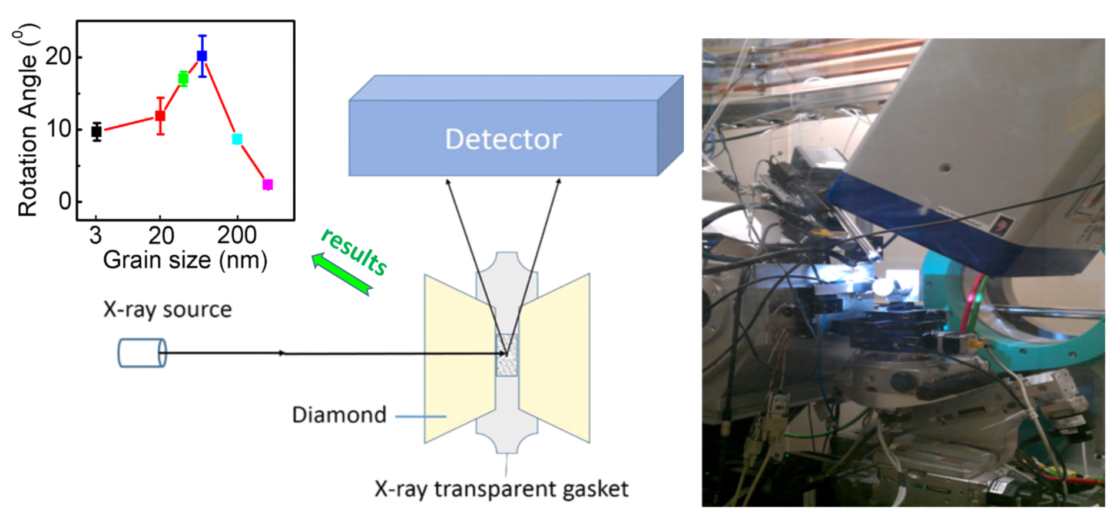

Using Laue x-ray microdiffraction at ALS Beamline 12.3.2, a group of scientists from the Center for High Pressure Science and Technology Advanced Research, the ALS, and UCLA monitored grain rotation markers in nanocrystalline nickel samples to determine, under high pressure, how the materials deformed. They examined a range of grain sizes, from 3–500 nm, and observed that 70-nm grains rotated more than other sizes. This result is contrary to conventional theory, based on the Read-Shockley model, which suggests that smaller grains rotate more under stress than larger ones, due to the motion of dislocations at the grain boundaries.

The researchers suspect that dislocations within the individual grains—a consideration not accounted for in theory—could explain the surprising result. This new finding has the potential to reshape our understanding of plastic deformation for a host of nanocrystalline metals, with implications for fundamental nanoscience and a wide range of industrial applications.

Work performed at ALS Beamlines 12.3.2 and 12.2.2.

X. Zhou, N. Tamura, Z. Mi, J. Lei, J. Yan, L. Zhang, W. Deng, F. Ke, B. Yue, and B. Chen, “Reversal in the size dependence of grain rotation,” Phys. Rev. Lett. 118, 096101 (2017), doi: 10.1103/PhysRevLett.118.096101.