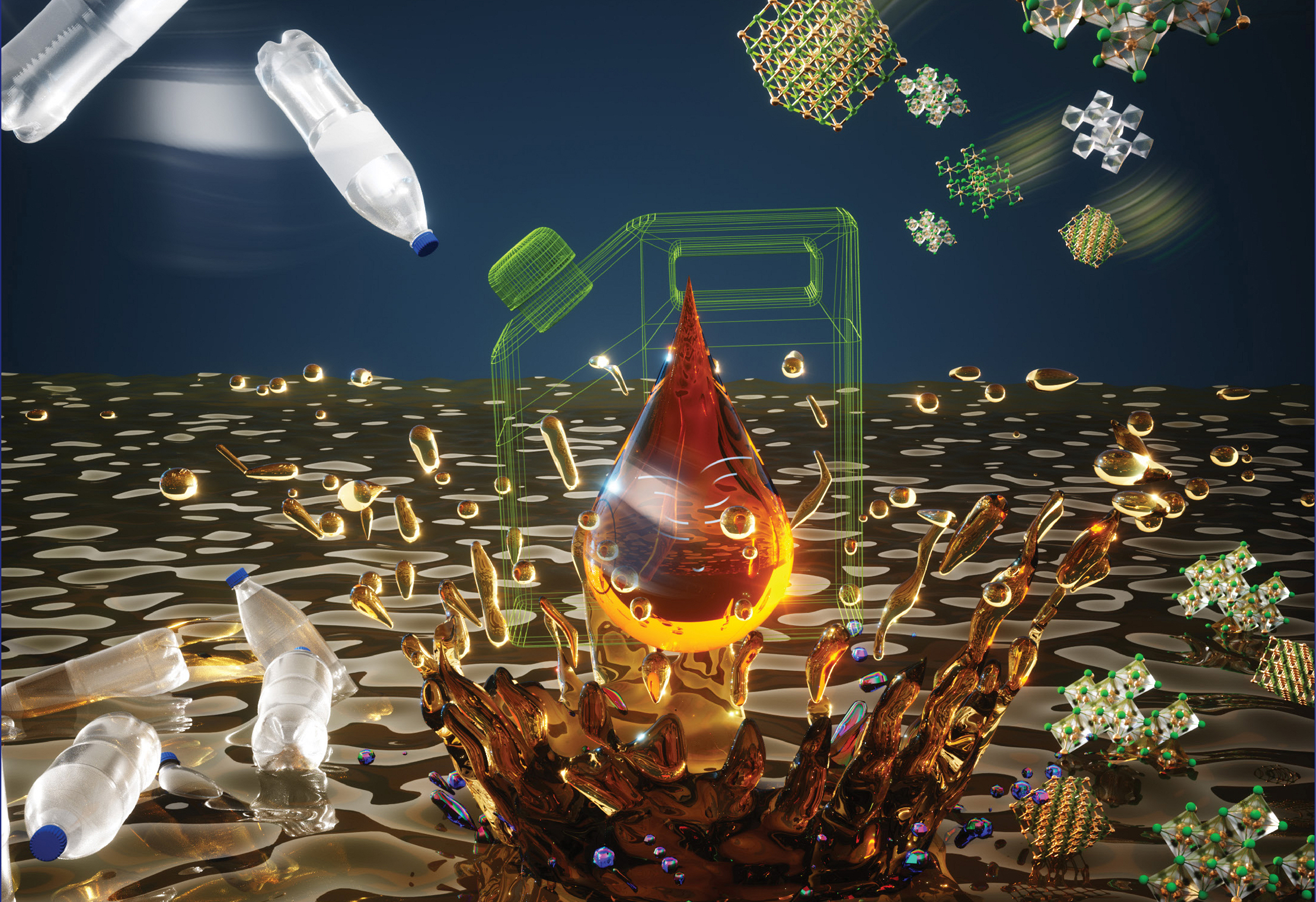

Plastic waste is a serious problem, especially with items meant to be used once and then thrown away. Such plastics are tough to break down, and current recycling methods either use a lot of energy or expensive materials. In this study, researchers aimed to develop a more sustainable, efficient, and selective approach for converting polyolefins (i.e., polyethylene and polypropylene, used in plastic bags and packaging) into valuable liquid chemicals.

“What we discovered is a simple way to turn this kind of plastic into useful liquid fuels, like components of gasoline or diesel, without needing high heat, rare metals, or added chemicals,” said Zhenzhen Yang, a Research and Development Associate in the Chemical Sciences Division at Oak Ridge National Laboratory. “This could be a big step toward turning plastic waste into something valuable instead of letting it pile up in landfills or oceans.”

The researchers studied a reaction mixture containing low-density polyethylene (LDPE) and AlCl3/NaCl, a special type of molten salt that can act like a super-reactive soup, breaking down the plastic efficiently. Using soft x-ray absorption spectroscopy (XAS) at Advanced Light Source (ALS) Beamline 7.3.1 combined with nuclear magnetic resonance measurements, the researchers probed the chemical bonding of aluminum species both at the surface (10 nm deep) and in the bulk (beyond 100 nm). The mixture was quenched (the reaction was halted) at different intervals without any post-treatment, to allow observation of the mixture’s evolution over time.

The results revealed dynamic AlCl4– and Al3+ species and their interactions with electron-rich intermediates. Strong Lewis-acid sites (which accept electron pairs) in the Al species actively facilitate C–C and C–H bond cleavage in LDPE without requiring external additives. This unexpected reactivity under mild, additive-free conditions highlights the powerful catalytic role of Al3+ in molten salts and opens new pathways for efficient plastic upcycling.

Over the long term, this approach could help reduce plastic pollution, support a circular economy by transforming waste into useful resources, and offer a scalable solution for industrial adoption. Ultimately, it presents a promising pathway to address the global plastic waste crisis with both environmental and economic advantages.

L. Qiu, F. Polo-Garzon, L.L. Daemen, M.-J. Kim, J. Guo, B.G. Sumpter, M. Koehler, C.A. Steren, T. Wang, L.T. Kearney, T. Saito, Z. Yang, and S. Dai, “Polyethylene upcycling to liquid alkanes in molten salts under neat and external hydrogen source-free conditions,” J. Am. Chem. Soc. 147, 19 (2025), doi:10.1021/jacs.5c01107.