Plastic solar cells that can be printed on flexible sheets with an ink-like solution show a lot of potential as a source of lightweight, inexpensive renewable energy. However, much of the power-conversion efficiency of such cells gets lost in the translation from small-scale lab studies to large-scale manufacturing processes. To help gain an understanding of why that happens, researchers have developed at the ALS a miniature version of an industrial-style (“slot-die”) printer that can operate in an x-ray beamline. With this capability, researchers can, for the first time, apply grazing-incidence x-ray diffraction (GIXD) and grazing-incidence small-angle x-ray scattering (GISAXS) to characterize active-layer formation in real time and at multiple length scales.

As can be imagined, the morphology or structure requirements to produce an efficient device are very demanding. The active layers are generally produced by solution-coating techniques that involve many rate-dependent processes such as solvent evaporation, phase separation, crystallization, and segregation of the components to the top and bottom of the film. As a consequence of these processes occuring at different rates, the active layers can become “trapped” in states very far removed from equilibrium, creating a major impediment to commercial fabrication. While we can characterize OPV structures in the laboratory and correlate the structures to performance, scaling up for manufacturing has been a major hurdle.Plastic solar cells, or organic photovoltaics (OPVs), consist of an active layer of electron-donor and electron-acceptor materials sandwiched between a pair of electrodes. Light is absorbed by the active layer to produce an exciton, a bound electron–hole pair, that diffuses to the donor/acceptor interface. There, the exciton converts into an electron and hole, and the two diffuse through continuous domains of electron and hole conductors to opposite electrodes, generating a current.

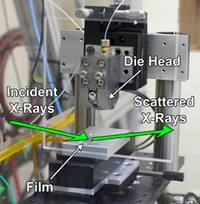

To address this challenge, researchers have constructed a miniature slot-die coating system that mimics commercial coaters and that can be installed directly into Beamline 7.3.3 at the ALS, where in situ x-ray scattering and diffraction can be performed as active-layer films are being coated onto either rigid or flexible electrode surfaces. Importantly, this mini-slot-die coater uses very small amounts of material, allowing the rapid and inexpensive screening of a large number of different materials. With the mini-slot-die coater in the x-ray beamline, researchers can watch the development of structures at size scales ranging from angstroms to thousands of angstroms under different drying conditions, and they can tune and balance the rate of solvent evaporation, phase separation, and crystallization to optimize performance on exactly the same devices for which they have the structural data. This represents a tremendous advance because, using only small amounts of material, they can discover exactly the chemical structure and processing conditions that will yield the best OPV device.

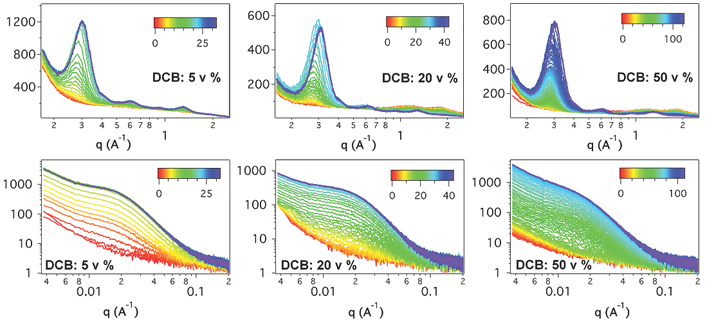

As an example, the researchers reported results for a solution of a donor polymer (DPPBT) and a complementary acceptor (PCBM), dissolved in chloroform (CF) and 1,2-dichlorobenzene (DCB) in several different concentrations (DCB = 5, 20, and 50 vol%). The GIXD and GISAXS data indicated that both phase separation and polymer ordering happened faster at lower DCB concentrations. In the case of 5% DCB, the rapid removal of the more volatile CF quickly concentrated the DPPBT:PCBM mixture well past the solubility limit, forcing a phase separation prior to crystallization of the DPPBT. Thus, the process through which the nanostructure forms in the printing process—a competition between crystallization and phase separation—is well tracked by in situ beamline experiments performed at the ALS. The average efficiency for this OPV was found to be 5.2%, among the highest for coated or printed solar cells. Knowledge about the morphology of the film with these exceptional results can subsequently be used to calibrate other systems.

Contact: Feng Liu

Research conducted by: F. Liu and T.P. Russell (U. of Massachusetts, Amherst, and Berkeley Lab); S. Ferdous (U. of Massachusetts); E. Schaible, A. Hexemer, and C. Wang (ALS); and M. Church and X. Ding (Jema Science Inc.).

Research funding: U.S. Department of Energy (DOE), Office of Basic Energy Sciences (BES). Operation of the ALS is supported by DOE BES.

Publication about this research: F. Liu, S. Ferdous, E. Schaible, A. Hexemer, M. Church, X. Ding, C. Wang, and T.P. Russell, “Fast Printing and In Situ Morphology Observation of Organic Photovoltaics Using Slot-Die Coating,” Adv. Mater. 27, 886 (2015). doi:10.1002/adma.201404040

ALS SCIENCE HIGHLIGHT #307