Global food and beverage giant PepsiCo has been using ALS x-ray tomography beamline 8.3.2 to understand more about the chemical structure and behavior of their starch-based snack foods, with the goal of creating a whole new category of snacks. While most of PepsiCo’s chips are cooked with traditional methods such as frying and baking, the company is currently exploring alternative heating methods, such as consumer microwave cooking, to give their customers a broader selection of snacks with desirable texture and lower fat content. PepsiCo is hopeful that their ALS research will move product development forward.

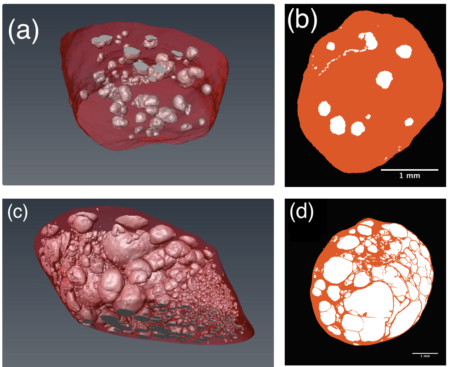

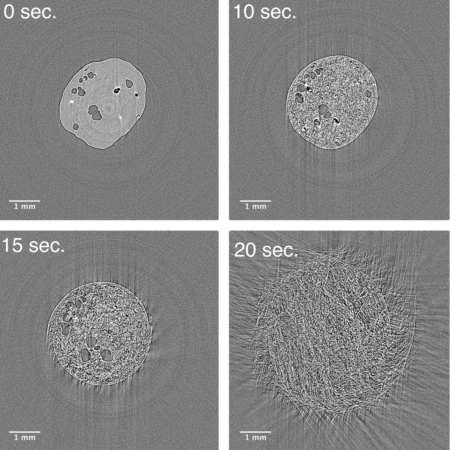

David Shuh, a senior scientist in Berkeley Lab’s Chemical Sciences Division, Stefano De Santis, a staff scientist in Berkeley Lab’s Accelerator Technology and Applied Physics Division, and ALS Beamline Scientist Dula Parkinson worked closely with PepsiCo to build a microwave waveguide system that could be used in the hutch of Beamline 8.3.2 to provide new data about the various starchy compositions of PepsiCo’s samples as they go through a microwave expansion process. PepsiCo has now completed four beam time sessions at the ALS, each time bringing a series of “pellets,” composed primarily of potato starch, for their imaging experiments. Using microtomography, an extremely high-resolution, 3D x-ray imaging technique, ALS scientists have been able to create real-time visualizations of the entire expansion process of these pellets. Over the course of 20 seconds, the structure of the pellets changes dramatically. The micron-scale resolution at the beamline makes it possible to map the internal structure of the starch pellets through this process.

“The pellet changes within seconds from a hard, glassy material into an aerated popped snack,” says John Bows, R&D director at PepsiCo. “With the images from 8.3.2 we are able to see minute details of pore-size distribution and cell-wall thickness.” How cell-wall thickness and pore-size distribution evolve into the final product is experienced as texture by the consumer, which is key to consumer acceptance levels, says Bows.

People tend to think of soft drinks when the name PepsiCo is mentioned, but the company actually has a much more diverse portfolio of products beyond their iconic sodas. About half of PepsiCo’s global revenues come from food products. PepsiCo owns the Lay’s and Doritos chip brands, as well as drinks like Gatorade and Tropicana orange juice.

As PepsiCo expands globally it is emphasizing its “Performance with Purpose” agenda, a vision to deliver long-term growth by integrating sustainability into business strategy. As such, the company has become even more interested in developing alternative, more energy-efficient technologies to frying and baking. Successful development of these processes requires a solid understanding of the underlying physics and engineering principles, says Bows.

Food materials present complex materials science and chemistry problems—heating leads to changes in material properties such as viscosity, density, and pore structure, and the final internal structure is a function of these properties, says Shuh. “Understanding how all of these properties integrate in a food product is key to development, and structure really determines product quality and consumer experience.”

Representatives from PepsiCo’s R&D division connected with Berkeley Lab scientists at a 2010 bio-energy conference, and after that forged ongoing relationships with both the ALS and the Molecular Foundry. In addition to their work at the ALS, PepsiCo recently completed a research project at the Foundry that gave the company some useful and novel solutions for barrier enhancement in their flexible packaging materials.

PepsiCo knew they had found a potential source of the scientific imaging they were after when they began their research at the ALS. “But until we did the first trial, I did not know it would be possible to image a pellet down to 3-micron resolution during heating,” Bows adds. “We were surprised that the first time we tried it we got such good fidelity from the beam.”

“Every time we do a beam run at the ALS, it gives PepsiCo developers more data to build on for product development,” Bows says. “It’s information we just can’t get any other way.”

Operation of the ALS is supported by the U.S. Department of Science, Office of Science, Basic Energy Sciences Program.

ALS INDUSTRY HIGHLIGHT #29