Catalytic systems based on bimetallic particles with controlled size, composition, and structure dispersed on a high-surface-area support are widely used for catalytic reforming, pollution control, alcohol oxidation, and electrocatalysis in fuel cells. Owing to the nanoscale size of the particles, the modification of the surface structure and composition that may occur when reaction conditions change can have dramatic effects on catalyst activity and selectivity. Working at the ALS, a University of California, Berkeley–Berkeley Lab group has used an ambient-pressure x-ray photoelectron spectroscopy (APXPS) apparatus to demonstrate that bimetallic nanoparticle catalysts can undergo profound structural and chemical changes in response to reactive environments at ambient pressures, thereby opening the way for engineering catalysts with enhanced activity and selectivity.

Bimetallic catalysts (featuring active sites with two or more metallic elements) provide examples of some of the most active and selective catalysts yet discovered. Their performance advantages derive from a kind of “synergy”: the two active metals somehow cooperate to enhance activity and/or selectivity relative to catalysts with only one metal. Nanoscale features such as surface structure and the distribution of the metals between the nanoparticle surface and core are known to control their activity, selectivity, and lifetime, but these features can change dramatically during the course of a reaction. Monitoring the changes has not been possible, owing to the combination of the nanometer dimensions of the catalyst particles and the pressures and temperatures typical of the reaction environment, but without this information it is difficult to design a catalyst that responds optimally to the shifting conditions.

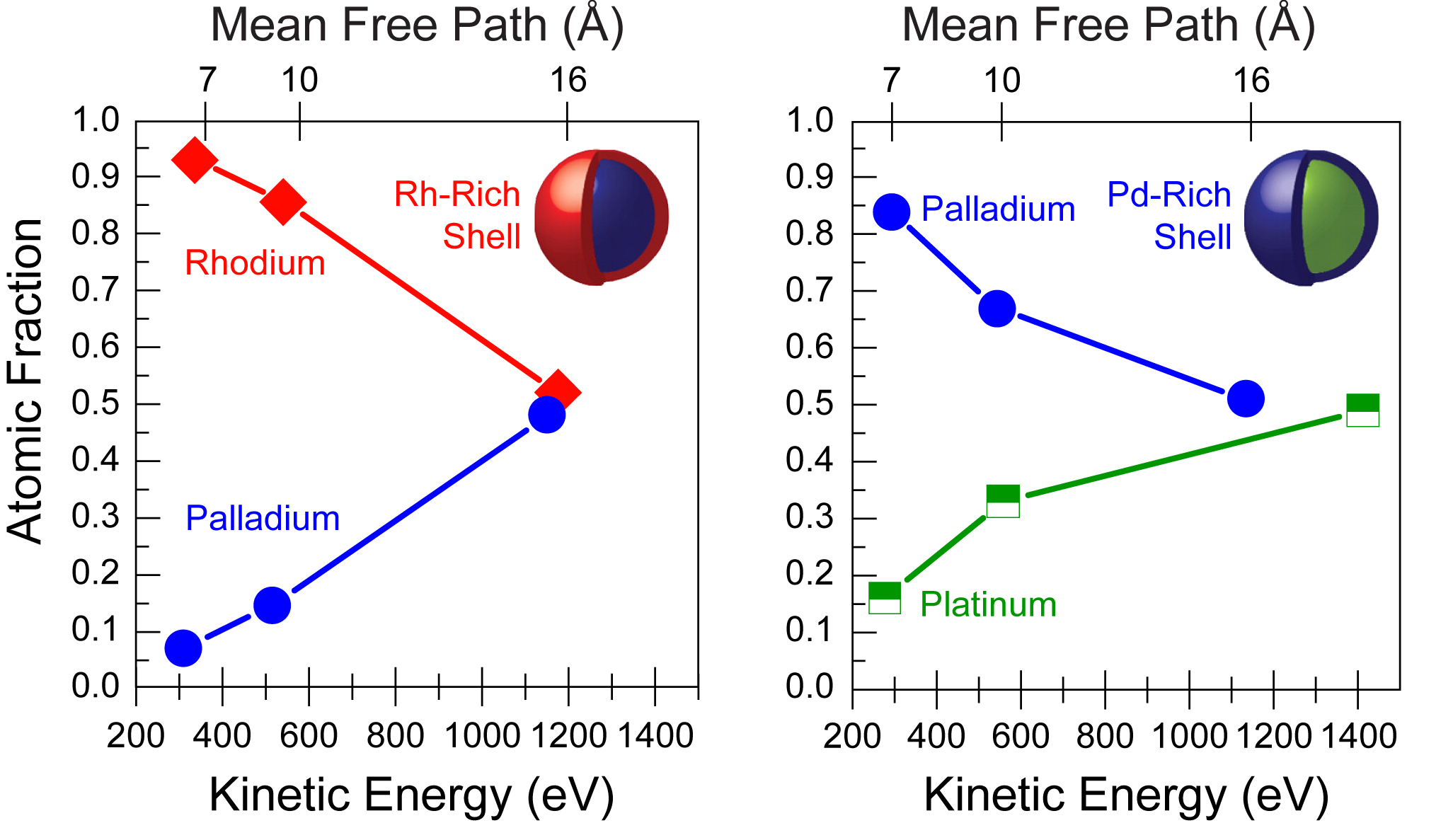

To investigate bimetallic catalysts under reaction conditions, the Berkeley group turned to x-ray photoemission spectroscopy on ALS Beamline 9.3.2, where there is a unique ambient-pressure photoemission chamber that allows measurements at pressures up to 10 Torr, owing to the very small distance (less than one electron mean free path) through which the easily scattered photoelectrons travel in gas. The group prepared model catalysts consisting of rhodium–palladium (Rh0.5Pd0.5) and platinum–palladium (Pt0.5Pd0.5) nanoparticles arrayed on silicon dioxide wafers. Using a series of incident photon energies, which produced photoelectrons of different mean free paths (escape depths), made it possible to create depth profiles of the particle composition and chemical state. The profiles roughly corresponded to a surface shell, which is usually the catalytically active area, surrounding an interior core.

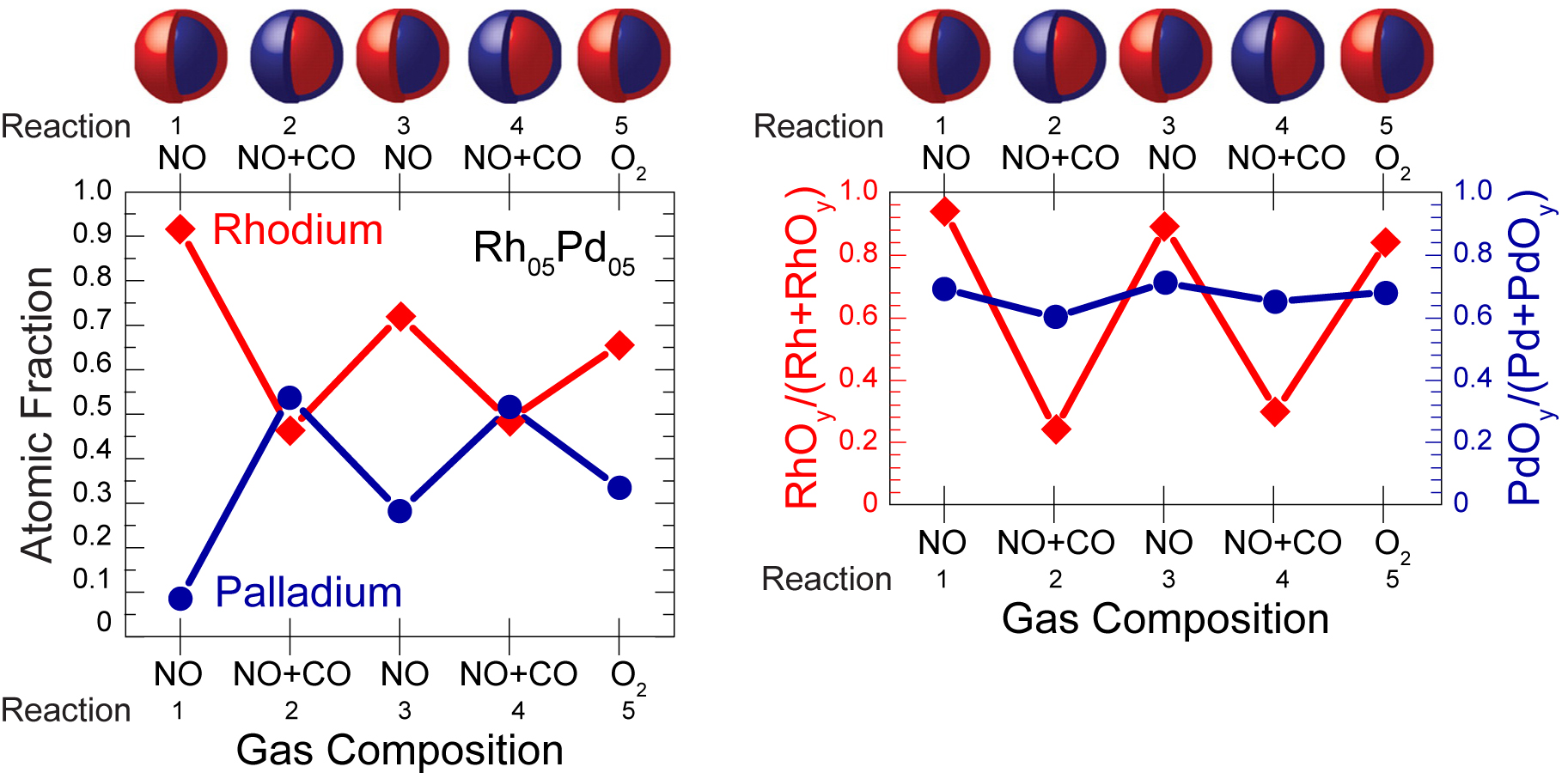

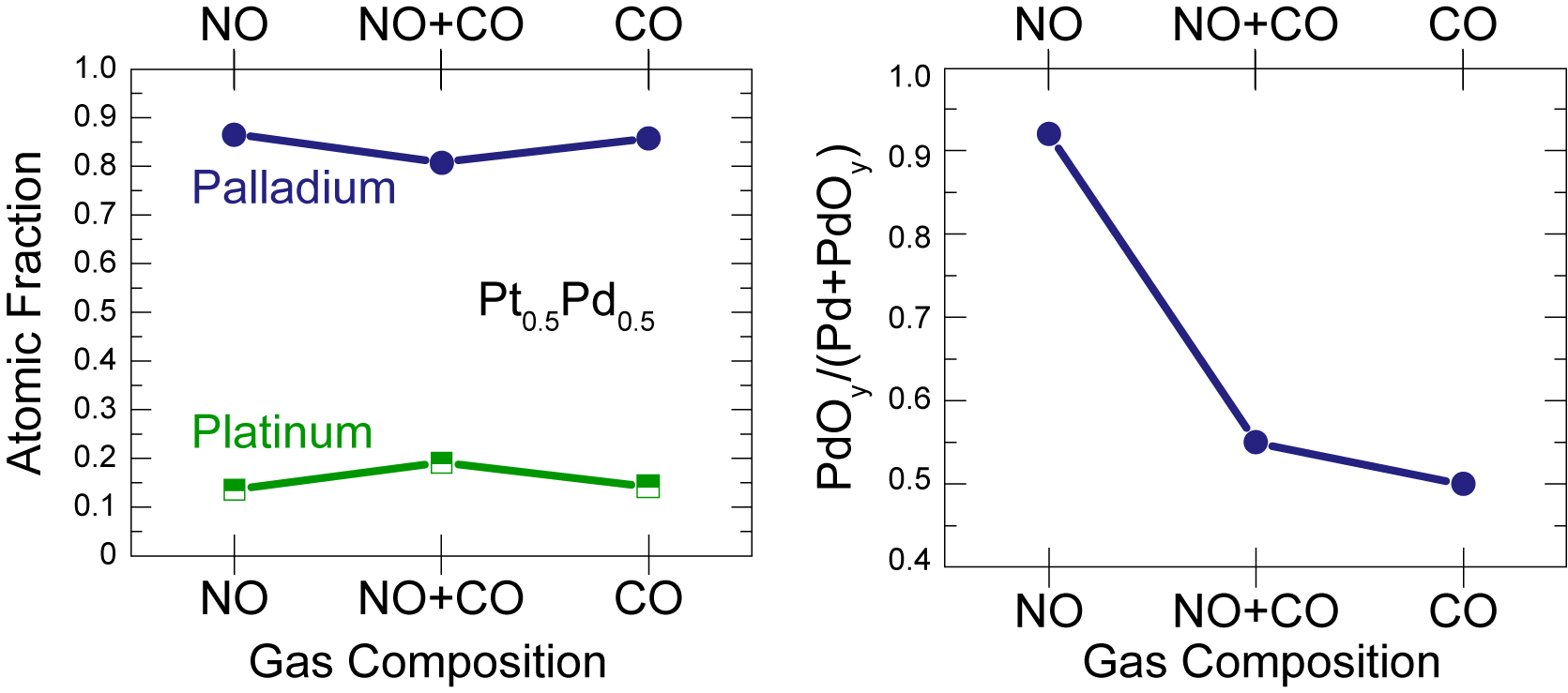

Measurements for each system began with as-prepared samples at room temperature in ultrahigh vacuum and continued with a sequence of measurements under oxidizing conditions (10 mTorr O2 or NO) at 300 °C, catalytic conditions (100 mTorr of NO and 100 mTorr of CO), and reducing conditions (100 mTorr CO or H2). The catalysts were also cycled between oxidizing and catalytic conditions to determine the reversibility of any composition changes observed. The group found that the as-prepared Rh0.5Pd0.5 nanoparticles had rhodium-rich shells and Pt0.5Pd0.5 nanoparticles had palladium-rich shells. Thereafter, the composition of the shell and the core-shell distribution of the constituent elements of the Rh0.5Pd0.5 nanoparticles changed dramatically but reversibly in response to changes in the ambient gas composition, whereas no substantial composition shifts occurred in the Pt0.5Pd0.5 nanoparticles other than oxidation of the palladium at the surface under oxidizing conditions.

The divergent restructuring behaviors of the two catalyst systems under the same reaction conditions illustrate the flexibility and tunability of bimetallic nanoparticle catalysts during catalytic reactions. The group believes that the restructuring offers an interesting way of controllably engineering the nanostructures for catalysis (or other applications) with the use of reactive gases. Designing new catalysts and shaping the catalytic properties of nanomaterials by structural engineering in reactive environments could ultimately yield “smart” catalysts whose structures change advantageously depending on the reaction environment.

Contacts: Gabor A. Somorjai or Miquel B. Salmeron

Research conducted by F. Tao, M.E. Grass, D.R. Butcher, J.R. Renzas, M. Salmeron, and G.A. Somorjai (Berkeley Lab and University of California, Berkeley); Y. Zhang (Berkeley Lab; University of California, Berkeley; and Peking University, China); Z. Liu (Berkeley Lab and ALS); and J.Y. Chung and B.S. Mun (ALS).

Research funding: U.S. Department of Energy, Office of Advanced Scientific Computing Research and Office of Basic Energy Sciences (BES). Operation of the ALS is supported by BES.

Publication about this research: F. Tao, M.E. Grass, Y. Zhang, D.R. Butcher, J.R. Renzas, Z. Liu, J.Y. Chung, B.S. Mun, M. Salmeron, and G.A. Somorjai, “Reaction-Driven Restructuring of Rh-Pd and Pt-Pd Core-Shell Nanoparticles,” Science 322, 932 (2008), doi:10.1126/science.1164170.

ALS SCIENCE HIGHLIGHT #179