Toyota has been conducting research at the ALS since 2010, using soft x-rays and the expertise and endstations at Beamline 6.3.1 to help them gain insight into the chemistry of electrolytes for use in magnesium-ion batteries. The hope is that the research eventually leads to a fully developed magnesium-based battery technology that would replace lithium ion batteries with essentially twice the energy in the same volume. One of the most valuable developments for Toyota thus far has been simply the proof that soft x-ray spectroscopy is an extremely useful tool for this research. The company hopes to increase the value of their soft x-ray research through a collaborative project with another Berkeley Lab DOE user facility focused on nanoscience research, the Molecular Foundry.

“What we’ve learned over the years as we develop more and more of these electrolytes is that they’re extremely complex for magnesium batteries,” says Toyota Scientist Timothy Arthur. “They are such complex systems with unique reactions happening at the interface that we need some additional support to really understand what’s happening.”

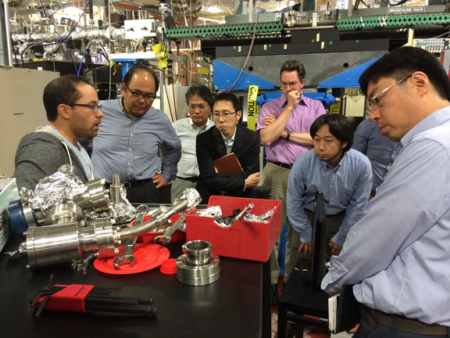

Toyota Manager Paul Fanson explains that there’s a certain limit to what Toyota can do with liquid-based samples by just looking at the spectra obtained at the beamline. Toyota wants to accelerate the process by simulating what the spectra would look like and developing new ideas based on those simulations in order to add some validation to their ALS experimental research. To accomplish this, Toyota turned to the director of the Molecular Foundry’s Theory of Nanostructured Materials Facility, David Prendergast.

“Spectroscopy is a technique that was traditionally used to fingerprint materials—you compare materials to a standard and if they match, then you know it’s the same as the standard,” explains Prendergast. “But for new materials, you often don’t have a standard as a reference point, so it’s really vital that you have theoretical support to do some simulation of your proposed model for the system.”

The Foundry’s Theory Facility is able to directly simulate many of the experiments at the ALS with predictive capabilities that enable scientists to revise experiments and complete their research more efficiently. These computationally intensive studies employ molecular dynamics and direct spectral simulations performed on Foundry computing resources and at the National Energy Research Scientific Computing Center (NERSC), another of Berkeley Lab’s DOE user facilities. The combination of the Beamline 6.3.1 endstation, which is one of a small number of endstations in the world that provides x-ray photons that can “see” magnesium, and the predictive capability of the Foundry is an ideal marriage, says Prendergast.

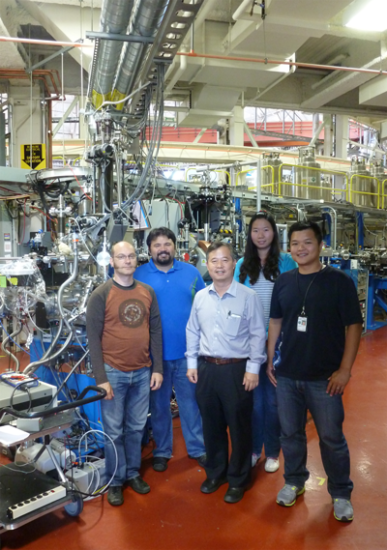

ALS Beamline 6.3.1 Staff Scientist Jinghua Guo hopes that the ALS-Molecular Foundry collaboration accelerates the research and development process for Toyota. The charge and discharge cycles for batteries can take days or months for each material type. “Trial and error is the traditional approach, but this project won’t be based merely on trial and error—the theoretical capabilities of the Foundry will help inform the process,” he says.

A small number of groups in the world are trying to look beyond lithium ion technology to new paradigms in energy storage, says Prendergast. He explains that one route is to look at multivalent ions, and magnesium is a promising material in this area. “Understanding how a magnesium battery works relies on having an understanding at the molecular level,” he says. “We don’t know in full detail the active species that are involved in the battery electrochemistry, but facilities like the Foundry and the ALS are enabling us to unravel this puzzle.”

Toyota’s user project at the Molecular Foundry has just started and they’re already working at ALS to collect data for the collaboration. Recently, Toyota was able to identify for the first time a key magnesium species from their original set of electrolytes. They’ll start by simulating what they believe to be the species with Prendergast, with the hope of adding more validity to what they believe to be a key intermediary for the magnesium deposition process.

Arthur and Fanson stress that it’s the relationships Toyota has built with scientists at the ALS and the Foundry that are key to their success. “Because of these folks and the capabilities at the ALS, we’ve gained insight into what’s happening at the battery interface that’s never been seen before with x-ray spectroscopy,” says Arthur.

“Anything in research comes with risk and with the possibility of not being able to solve the challenges,” says Fanson. “ If we’re successful, it could certainly be revolutionary for personal electronics and electric or plug-in hybrid vehicles.”