SCIENTIFIC ACHIEVEMENT

Using the Advanced Light Source (ALS), researchers found quantitative correlations between processing parameters and the structure of ultrafine, polymer-reinforced carbon-nanotube fibers.

SIGNIFICANCE AND IMPACT

The work will facilitate the production of high-strength materials, including those needed for positioning target capsules for fusion research at the National Ignition Facility.

A new twist in nanotubes

Carbon nanotubes are remarkable structures: conductive, lightweight, and incredibly strong. But despite decades of research, it remains unclear how to retain these properties when scaling up to the macroscale.

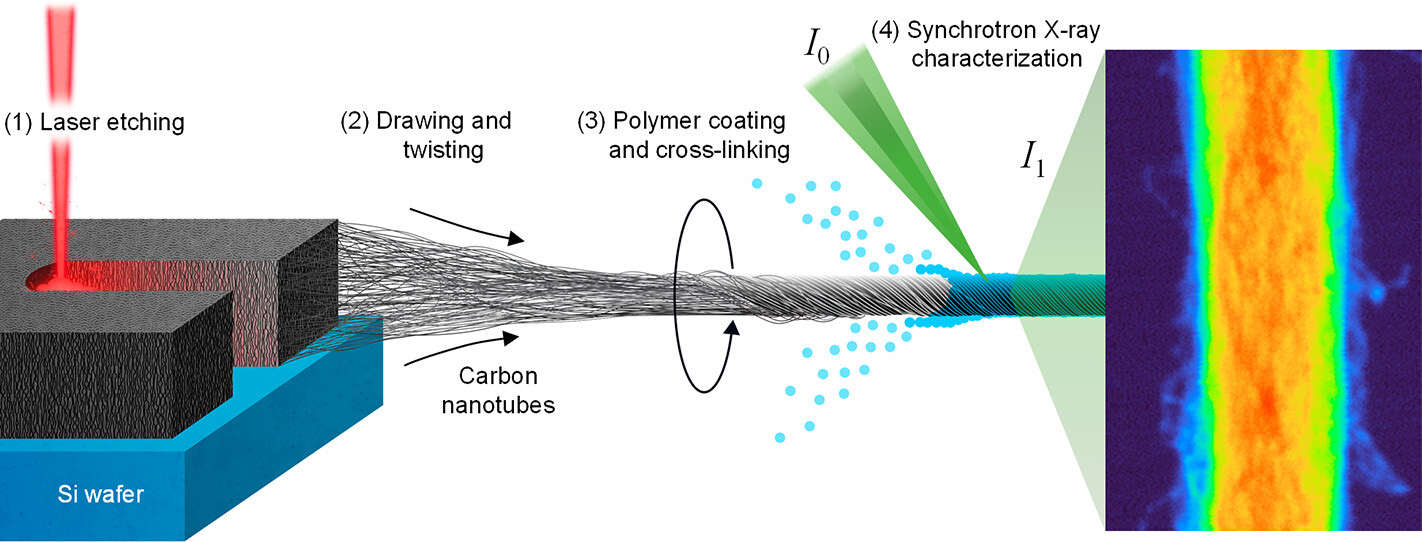

At Lawrence Livermore National Laboratory, researchers developed a promising approach. They made twist-spun yarns out of individual carbon nanotubes and coated the resulting fibers with polymers to stitch together neighboring nanotubes, boosting mechanical performance. However, further development required more details about the internal structure of these polymer-nanotube composites. In particular, the researchers sought to understand how processing parameters influence key structural features such as nanotube alignment, density, porosity, and polymer loading.

In this work, the Livermore researchers used synchrotron x-ray techniques to analyze the hierarchical, twisted morphology of carbon-nanotube yarns and their composites. Such high-tensile-strength fibers are of interest as a way to support target capsules for inertial confinement fusion experiments at the National Ignition Facility (NIF). The fibers may also be useful for wearable electronics and smart textiles, or artificial muscles and neurons.

The art of nanotube spinning

The Livermore team has been working to push the boundaries of mechanical performance in vanishingly thin carbon-nanotube yarns with diameters well below 5 micrometers. They recently developed a promising approach using the deposition of vapor-phase polymers and thermal cross-linking to effectively distribute mechanical loads across neighboring carbon nanotubes in twist-spun yarns, resulting in a 300% increase in material stiffness (Young’s modulus).

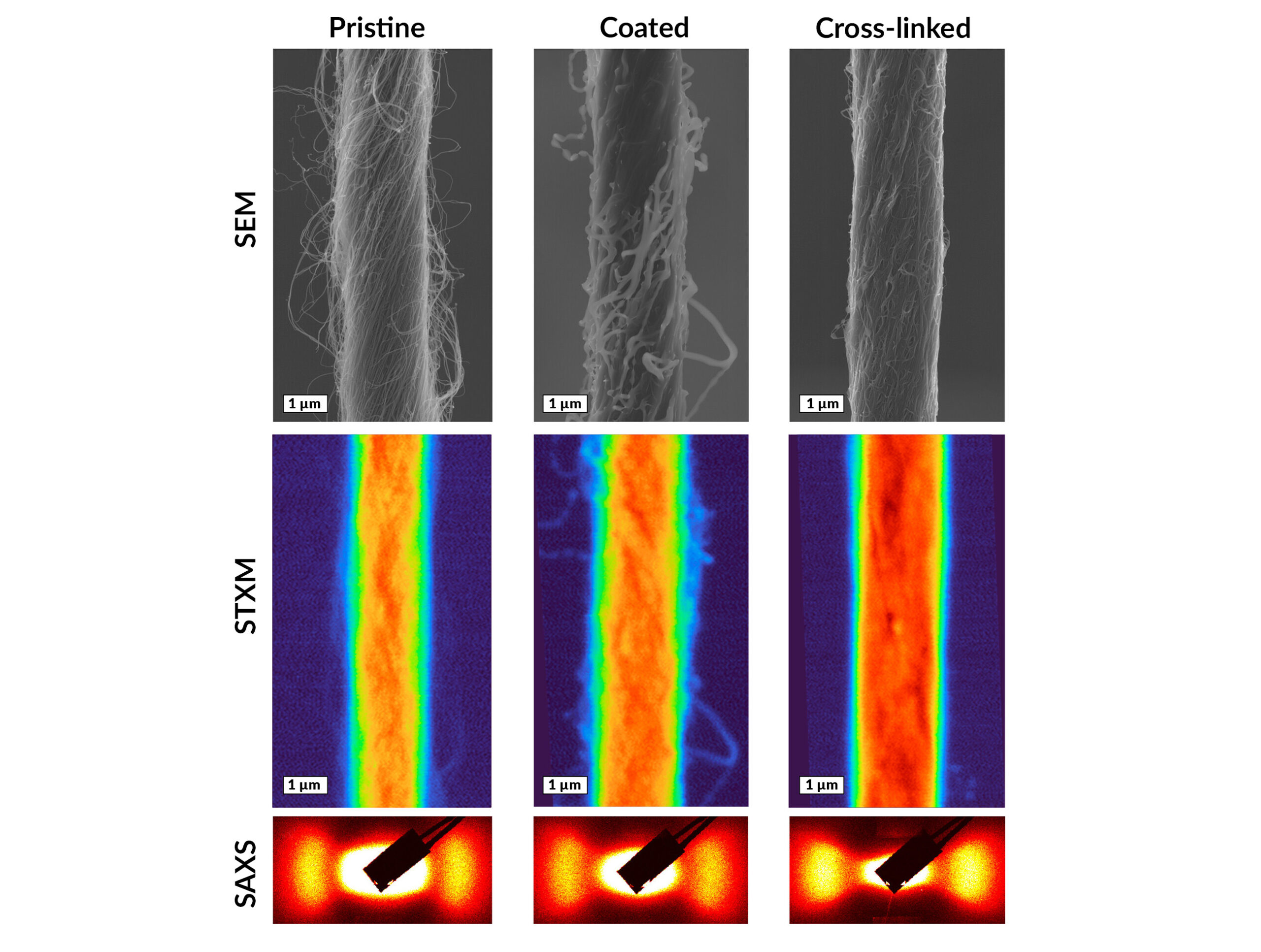

In previous work, this finding was corroborated using small-angle x-ray scattering (SAXS) at ALS Beamline 7.3.3. The scattering data provided hints that the polymer infiltration was influencing the structure of the nanotubes within the yarn, but a more detailed and quantitative picture was needed to understand the connections between processing, structure, and properties.

Threading the energy needle

To this end, the researchers employed a combination of complementary soft x-ray techniques at the ALS, including scanning transmission x-ray microscopy (STXM) at Beamline 5.3.2.2, which enabled nanoscale imaging and density mapping with elemental specificity, and SAXS at Beamline 11.0.1.2, to analyze the nanotube alignment and bundling structure.

The ALS was critical to this study because it is optimized for low energies, enabling the analysis of inherently thin and low-Z materials. The STXM beamline enabled quantitative spectromicroscopy across the carbon and oxygen K edges for analysis of the nanotubes and polymers independently, all with 30 nm resolution, while the soft x-ray scattering beamline provided ample scattering contrast not attainable at traditional high-energy SAXS beamlines.

Process–structure correlations

The data revealed a ubiquitous inverse relationship between density and diameter (density ~ diameter-2), highlighting bounding limits for fabricating ultrathin, dense yarns. The results also confirmed that the vapor-phase polymer infiltration approach produces a uniform and near-perfect filling of the voids between nanotubes without altering the nanotube alignment, which explains the excellent mechanical performance.

The information from these experiments provides valuable feedback into ongoing material-development efforts at NIF, advancing us toward realizing fusion as a sustainable energy source. Future work will continue to push the performance of nanotube yarns, seeking to elucidate the dynamic structural evolution of these materials under applied mechanical loads.

Contacts: Eric Meshot and Xavier Lepró

Researchers: E.R. Meshot (Lawrence Livermore National Laboratory and Atomic Machines Inc.); A. Baker, D. Malone, S. Hayes, H. Hamza, and X. Lepró (Lawrence Livermore National Laboratory); and C. Wang and M.A. Marcus (ALS).

Funding: Laboratory Directed Research & Development (LDRD) program 20-ERD-023 (Lawrence Livermore National Laboratory) and US Department of Energy (DOE), National Nuclear Security Administration. Operation of the ALS and Molecular Foundry is supported by DOE, Office of Science, Basic Energy Sciences program.

Publication: E.R. Meshot, A. Baker, D. Malone, S. Hayes, H. Hamza, C. Wang, M.A. Marcus, and X. Lepró, “High-Resolution X-ray Spectromicroscopy Reveals Process-Structure Correlations in sub-5-μm Diameter Carbon Nanotube-Polymer Composite Dry-Spun Yarns,” ACS Nano 17, 10589 (2023), doi:10.1021/acsnano.3c01537.

ALS SCIENCE HIGHLIGHT #497