When it comes to metal catalysts, platinum is the standard. However, at about $2,000 an ounce, the high cost of the raw material presents major challenges for the future wide-scale use of platinum in fuel cells. Berkeley Lab research suggests that one possible way to meet these challenges is to think small. Researchers from Berkeley Lab’s Materials Sciences Division have found that under high pressure—comparable to the pressures at which many industrial technologies operate—platinum surfaces can change their structure dramatically in response to the presence of high-coverage reactants. High-pressure scanning tunneling microscopes (STM) and ambient-pressure x-ray photoelectron spectroscopy (AP-XPS) at ALS Beamlines 9.3.2 and 11.0.2 allowed researchers to study catalysts’ structure and composition under realistic conditions.

Researchers have discovered that the presence of high densities of carbon monoxide (CO) molecules can reversibly alter the catalytic surfaces of platinum single crystals, which are thermodynamically stable under vacuum or low-coverage conditions. On the other hand, platinum nanoclusters become more stabilized as carbon monoxide molecules are adsorbed at high densities because they provide a relief to the strong lateral repulsion experienced in flat areas of the metal surface.

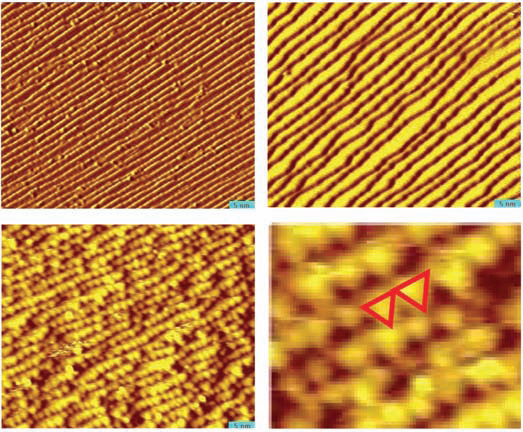

In this study, single-crystal platinum surfaces were examined under high pressure using STM. They were structured as a series of flat terraces about six atoms wide separated by atomic steps. Atomic steps and kinks are common features in metal catalysts and are considered to be the active sites where catalytic reactions occur. For that reason, stepped single-crystal surfaces are widely used as models of real catalysts.

Industrial catalysts typically operate under a wide range of pressures and temperatures. However, surface-science experiments have traditionally been performed under high-vacuum conditions at low temperatures. The ability to observe catalytic surfaces at the atomic and molecular levels under actual reaction conditions is the only way large-scale surface restructuring of platinum crystals could be detected.

The platinum surfaces were covered with carbon monoxide gas, a reactant involved in many important industrial catalytic processes, including the Fischer-Tropsch process for making liquid hydrocarbons, the oxidation process in automobile catalytic converters, and the degradation of platinum electrodes in hydrogen fuel cells. As the carbon monoxide coverage of the platinum surfaces increased, the terraces widened; at one-torr pressure when the coverage of CO approached 100%, they fractured into nanometer-sized clusters due to increased lateral repulsion between molecules. The flat terraces re-formed when carbon monoxide gas was removed. This large-scale surface restructuring of stepped platinum highlights the strong connection between coverage of reactant molecules and the atomic structure of the catalyst surface.

Using STM and AP-XPS, researchers were able to determine the geometry and location of the catalyst atoms when the surfaces are covered with dense layers of molecules, as occurs during a chemical reaction.

Scientists imaged the atomic structure and identified the chemical state of catalyst atoms and adsorbed reactant molecules under industrial-type pressures and temperatures. STM images revealed the formation of nanoparticle clusters of platinum on the platinum crystal surfaces, and the AP-XPS spectra revealed a change in carbon monoxide electron binding energies.

The next steps will be to determine whether other adsorbed reactants, such as oxygen or hydrogen, also result in the creation of nanoclusters in platinum. Exploring metals that catalyze other important reactions—such as palladium, silver, copper, rhodium, iron, and cobalt—might also help researchers determine whether nanoclusters can be induced to form under high coverage of adsorbed reactants. If this nanoclustering is a general phenomenon, it could have major consequences for high-pressure, high-temperature catalytic reaction conditions.

Contacts: Gabor A. Somorjai or Miquel B. Salmeron

Research conducted by D.R. Butcher, F. Tao, M. Salmeron, and G.A. Somorjai (Berkeley Lab and University of California, Berkeley) and H. Bluhm, S. Dag, Z. Liu, and L.-W. Wang (Berkeley Lab).

Research funding: U.S. Department of Energy (DOE), Office of Basic Energy Sciences (BES). Operation of the ALS is supported by DOE BES.

Publication about this research: F. Tao, S. Dag, L.-W. Wang, Z. Liu, D.R. Butcher, H. Bluhm, M. Salmeron and G.A. Somorjai, “Break-up of stepped platinum catalyst surfaces by high CO coverage,” Science 327, 850 (2010), doi:10.1126/science.1182122.

ALS SCIENCE HIGHLIGHT #216