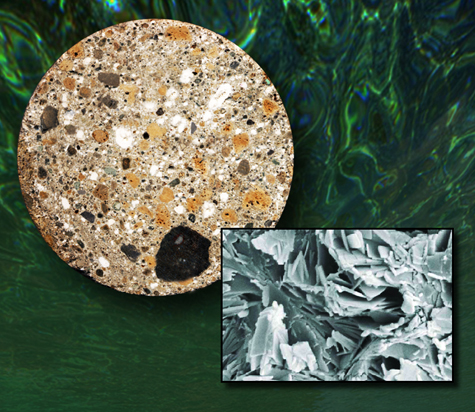

The material secrets of a concrete Roman breakwater that has spent the last 2000 years submerged in the Mediterranean Sea have been uncovered by an international team of researchers using a variety of techniques, including x-ray microdiffraction, x-ray spectroscopy, and synchrotron-based high-pressure x-ray diffraction. Analyses of the ancient samples pinpointed why the best Roman concrete was superior to most modern concrete in durability, why its manufacture was less environmentally damaging, and how these improvements could be adopted in the modern world.

The most common type of cement used today is called Portland cement, from its similarity to a type of stone that was quarried on the Isle of Portland in Dorset, England. The ancient Romans, however, made concrete by mixing lime and volcanic rock. For underwater structures, lime and volcanic ash were mixed to form mortar, and this mortar and volcanic tuff were packed into wooden forms. The seawater instantly triggered a hot chemical reaction. The lime was hydrated—incorporating water molecules into its structure—and reacted with the ash to cement the whole mixture together.

Using Beamlines 5.3.2.1, 12.2.2, and 12.3.2 along with other experimental facilities at UC Berkeley, the King Abdullah University of Science and Technology in Saudi Arabia, and the BESSY synchrotron in Germany, the researchers investigated maritime concrete from Pozzuoli Bay in Italy. They found that Roman concrete differs from the modern kind in several essential ways. One is the kind of glue that binds the concrete’s components together. In concrete made with Portland cement, this is a compound of calcium, silicates, and hydrates (C-S-H). Roman concrete produces a significantly different compound—one with added aluminum and less silicon. The resulting calcium-aluminum-silicate-hydrate (C-A-S-H) is an exceptionally stable binder. At ALS Beamline 5.3.2.1, x-ray spectroscopy showed that the specific way the aluminum substitutes for silicon in the C-A-S-H may be the key to the cohesion and stability of the seawater concrete.

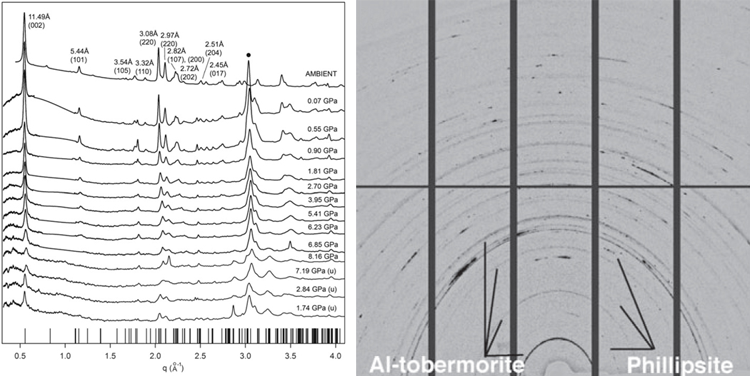

Another striking find concerns the hydration products in concrete. In theory, C-S-H in concrete made with Portland cement resembles a combination of naturally occurring layered minerals, called tobermorite and jennite. Although these crystals are nowhere to be found in conventional modern concrete, Al-tobermorite (Al for aluminum) occurs in the mortars of all the ancient seawater concretes studied so far. High-pressure x-ray diffraction at Beamline 12.2.2 measured its mechanical properties for the first time and clarified the role of aluminum in its crystal lattice. Al-tobermorite has a greater stiffness than poorly crystalline C-A-S-H and provides a model for concrete strength and durability in future concretes made with environmentally friendly supplemental materials. Finally, microdiffraction studies at Beamline 12.3.2 showed that Al-tobermorite crystallized in the cementitious matrix that binds the Roman concrete, followed by crystallization of the zeolite crystal, phillipsite. Integration of the results from various beamlines revealed the ancient mortar’s potential applications for high-performance concretes, including the encapsulation of hazardous wastes.

Environmentally friendly modern concretes already include volcanic ash or fly ash from coal-burning power plants as partial substitutes for Portland cement, with good results. These blended cements also produce C-A-S-H, and with these studies, their long-term performance can be more fully determined. The analyses showed that the Roman recipe needed about 10% lime by weight, made at two-thirds or less the temperature required by Portland cement. Lime reacting with aluminum-rich pozzolanic volcanic ash and seawater formed highly stable C-A-S-H and Al-tobermorite, insuring strength and longevity. Both the materials and the way the Romans used them hold lessons for the future. The ancient concretes provide a sustainable prototype for producing Al-tobermorite in high-performance concretes with natural volcanic ash. The proven endurance of the crystals in seawater for 2000 years indicates exceptionally high durability in a complex pozzolanic concrete composite, on a par with the stable rock forming cementitious minerals of the earth’s crust.

Contacts: Paulo Monteiro and Marie Jackson

Research conducted by: M.D. Jackson, S.R. Chae, S.R. Mulcahy, R. Taylor, H.-R. Wenk, and P.J.M. Monteiro (Univ. of California, Berkeley); J. Moon (Univ. of California, Berkeley, and Stony Brook University); P. Li (Tsinghua University, China); E. Gotti (CTG Italcementi S.p.A., Italy); M. Kunz (ALS); A.-H. Emwas (King Abdullah Univ. of Science and Technology, Saudi Arabia); C. Meral (Univ. of California, Berkeley, and Middle East Technical Univ., Turkey); P. Guttmann (Helmholtz-Zentrum für Materialien und Energie GmbH, Germany); P. Levitz (Université Pierre et Marie Curie, France); S. Yoon (Univ. of California, Berkeley, and Univ. of Aberdeen, UK); and G. Vola (Cimprogetti S.p.A, Italy).

Research funding: King Abdullah University of Science and Technology, Saudi Arabia; the Loeb Classical Library Foundation, Harvard University; and the U.S. Department of Energy (DOE), Office of Basic Energy Sciences (BES). Samples of Roman maritime concrete were provided by Marie Jackson and by the ROMACONS drilling program, sponsored by CTG Italcementi of Bergamo, Italy. Operation of the ALS is supported by DOE BES.

Publications about this research: M.D. Jackson, J. Moon, E. Gotti, R. Taylor, S.R. Chae, M. Kunz, A.-H. Emwas, C. Meral, P. Guttmann, P. Levitz, H.-R. Wenk, and P.J.M. Monteiro, “Material and Elastic Properties of Al-Tobermorite in Ancient Roman Seawater Concrete,” J. Am. Ceram. Soc. 96, 2598 (2013), doi:10.1111/jace.12407; M.D. Jackson, S.R. Chae, S.R. Mulcahy, C. Meral, R. Taylor, P. Li, J. Moon, S. Yoon, A.-H. Emwas, G. Vola, H.-R. Wenk, and P.J.M. Monteiro, “Unlocking the secrets of Al-tobermorite in Roman seawater concrete,” Am. Mineral. 98, 1669 (October 2013), doi:10.2138/am.2013.4484.

ALS SCIENCE HIGHLIGHT #280

There has been a great deal of popular interest in the results of the research, and responses to the original press release registered as first place on the Reddit and Futurity Web sites on June 5, 2013.